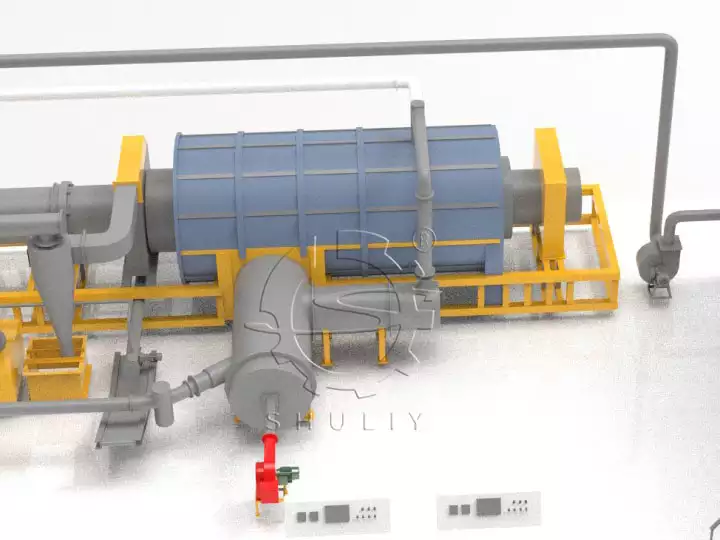

Mashine mpya ya Shuliy ya kutengeneza mkaa ni mashine ya kabonishaji ya kuendelea iliyoboreshwa, ikibadilisha ukungu wa mkaa, maganda ya nazi, unga wa mchele, n.k. kuwa mkaa wa ubora kwa joto kali. Ukubwa wa malighafi ni 3-10mm, na unyevu ni <15%.

Mashine hii ya kabonishaji mkaa ina uwezo wa 500-3000kg/h, na sifa za matumizi mbalimbali, urekebishaji na kabonishaji endelevu. Ikiwa unatafuta tanuru nzuri ya kabonishaji, ni chaguo nzuri kwako.

Vipengele vya mashine ya kaboni ya makaa ya mawe iliyoboreshwa

Toleo lililoboreshwa la mashine ya kutengeneza mkaa linatokana na mashine ya jadi ya mkaa kwa maboresho kadhaa. Inaboresha ufanisi wa uzalishaji, inapunguza matumizi ya nishati, inaongeza ubora wa bidhaa na ni rafiki zaidi kwa mazingira.

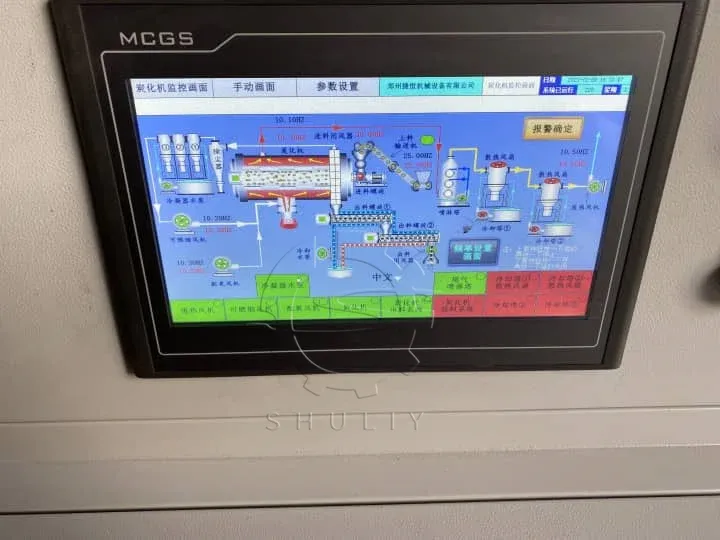

Kiwango cha juu cha automatisering

- Mfumo wa kuingiza kiotomatiki: kuingiza kiotomatiki kunaweza kufanikishwa, kupunguza kazi za mikono na kuboresha ufanisi wa uzalishaji.

- Udhibiti wa joto kiotomatiki: kupitia mfumo wa udhibiti wa akili, unaweza kudhibiti kwa usahihi joto la kuchoma ili kuhakikisha ubora wa bidhaa thabiti.

- Mfumo wa kutoa kiotomatiki: kutoa makaa yaliyomalizika kiotomatiki kutoka kwenye tanuru, kupunguza mzigo wa kazi.

Ufanisi wa juu na uokoaji wa nishati

- Mfumo wa urejeshaji wa joto: kurejesha joto lililotolewa wakati wa mchakato wa kaboni na kulitumia kwa kupasha joto malighafi, kupunguza matumizi ya nishati.

- Tabaka la adiabatic: : nyenzo ya insulation yenye ufanisi mkubwa wa joto hupunguza kupoteza joto na kuboresha matumizi ya nishati.

- Mfumo wa uboreshaji wa mwako: burna yenye ufanisi mkubwa kuhakikisha mwako kamili na kuboresha ufanisi wa joto.

Utendaji wa mazingira bora

- Mfumo wa kusafisha gesi ya mtaa: kusafisha gesi ya mtaa inayotolewa wakati wa mchakato wa kaboni ili kupunguza utoaji wa vichafuzi.

- Ufungaji mzuri: tanuru imefungwa vizuri ili kuzuia miale hatari na kulinda mazingira.

Ubora wa bidhaa wa juu

- Udhibiti sahihi wa joto: udhibiti sahihi wa joto la kaboni unahakikisha ubora wa makaa thabiti na kiwango cha juu cha kaboni thabiti.

- Mfumo kamili wa kupozea: tumia mfumo wa kupozea wenye ufanisi mkubwa ili kupozea makaa kwa haraka na kuzuia kuungua kwa ghafla.

Uwezo mkubwa wa kubadilika

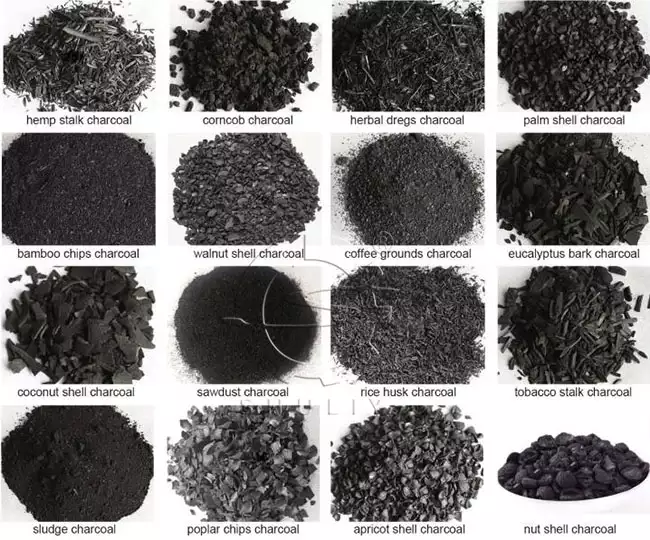

- Uwezo wa kazi nyingi: inaweza kuchakata aina nyingi za malighafi za biomass, kama vile vipande vya mbao, vumbi la mbao, maganda ya mchele, maganda ya karanga na kadhalika.

- Rahisi kuendesha: uendeshaji rahisi na matengenezo rahisi.

Kiwaelewa

- Ufuatiliaji wa mbali: ufuatiliaji wa mbali wa hali ya uendeshaji wa vifaa.

- Uchambuzi wa data: kukusanya na kuchambua data za uzalishaji ili kutoa msingi wa uboreshaji wa uzalishaji.

Vigezo vya kiufundi vya mashine mpya ya makaa

| Mfano | Nishati | Uwezo | Volti ya taifa | Volti maalumu |

| SL-0508 | 42KW | 500KG/H | 31W | 31.5W |

| SL-0812 | 49KW | 1000KG/H | 43W | 44.5W |

| SL-1015 | 54KW | 2000KG/H | 56W | 58W |

| SL-1218 | 59KW | 3000KG/H | 80W | 83W |

Malighafi zinazobadilishwa na mashine ya kutengeneza makaa ya Shuliy

Tanuru yetu ya kutengeneza mkaa ina matumizi pana, kama vile:

- Vifaa vya mbao: mbao zilizokatwa, ukungu wa mkaa, vipande vya mkaa, matawi, maganda, n.k.

- Takataka za kilimo: unga wa mchele, maganda ya karanga, mashimo ya mahindi, bagasse, n.k.

- Maganda ya matunda: maganda ya nazi, maganda ya walnut, mbegu za apricot, n.k.

- Bamboo: chuma za mianzi, vipande vya mianzi, n.k.

- Matope ya mijini, matope ya mji, matope ya viwandani, na mengineyo

- Takataka ngumu za miji

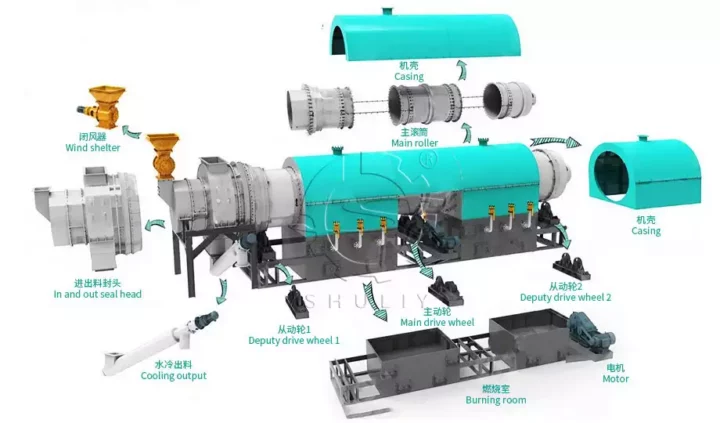

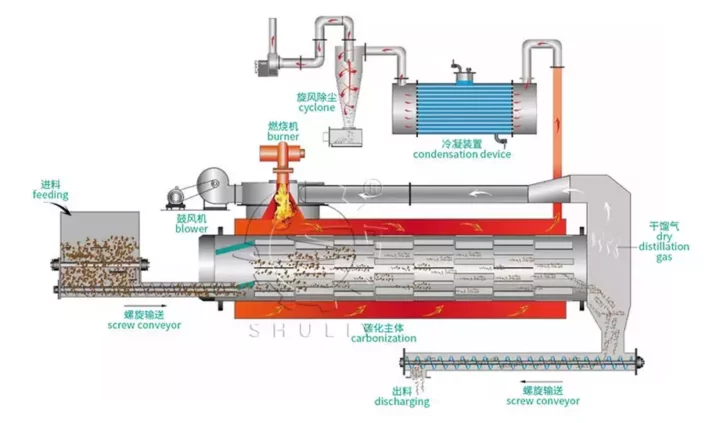

Nini kinaunda tanuru hii ya kaboni ya makaa ya mawe?

Muundo wa mashine mpya ya Shuliy ya kutengeneza mkaa unajumuisha kizibo, mwili wa kabonishaji, njia ya kutolea, n.k.

Wateja wengine wana mahitaji kabla ya kabonishaji, kwa hivyo, kifaa cha kusaga kimewekwa kabla ya tanuru ya kabonishaji.

Mchoro wa mtiririko wa kazi wa tanuru ya kutengeneza makaa

- Kuingiza: nyenzo inayobadilishwa kuwa kaboni huingizwa kwenye tanuru kupitia kifaa cha kuingiza.

- Kupasha joto: nyenzo inapashwa joto ili kuondoa unyevu.

- Kaboni: chini ya hali ya joto la juu, unyevu na vitu vya mvuke kwenye nyenzo vinatolewa na sehemu ngumu inakabuliwa.

- Kupozwa: makaa yanapozwa hadi joto la chumba.

- Kutoa: makaa yaliyopozwa yanatolewa kutoka kwenye tanuru.

Je, bei ya mashine ya kutengeneza makaa ni nini?

Bei ya mashine ya kabonishaji ya Shuliy itategemea mambo mengi, kama mfano wa vifaa, kiwango cha uzalishaji, kiwango cha uendeshaji wa kiotomatiki, usanidi, nyenzo na kadhalika. Bei ya seti kamili ya mistari ya uzalishaji ya kabonishaji itatofautiana kulingana na mahitaji maalum.

Ikiwa unataka kujua bei sahihi zaidi, tunapendekeza utupe habari zifuatazo:

- Je, mahitaji yako ya uzalishaji wa kila siku ni yapi?

- Unataka kiwango gani cha uendeshaji wa kiotomatiki kwa vifaa?

- Je, una mahitaji gani kwa nyenzo za vifaa?

- Je, una upendeleo wa chapa?

Tutakutumia ofa bora kulingana na mahitaji yako.

Mahitaji ya usakinishaji

Baada ya kununua mashine ya kutengeneza mkaa, usakinishaji ni kazi kubwa. Kwa kumbukumbu yako, kuna mahitaji kadhaa ya usakinishaji.

- Mahitaji ya mafuta

- >10 MJ/kg OS (= nyenzo asilia)

- 75% OS (nyenzo kavu)

- <30 mm

- Vigezo vya muunganisho

- Umeme (380V, awamu 3)

- Gesi asilia (CNG, LPG) 100 mbar

- Maji + maji taka

- Nitrojeni na hewa iliyobanwa

- Intaneti

- Uwezo wa msingi wa msingi

- >325 kN

- Mahitaji ya nafasi ya chini kabisa

- 150 m²

- Mahitaji ya wafanyakazi

- Uzoefu wa kuendesha vifaa vinavyohusiana

- Uzoefu wa kushughulikia dharura

- Vigezo vya sera

- Kumridhisha mazingira ya kienyeji na vigezo vingine vya sera

Vifaa vya uzalishaji wa makaa yanayohusiana

Kama mtengenezaji mtaalamu wa mashine za kutengeneza mkaa, mbali na tanuru hii ya mkaa, pia tuna:

- Mashine ya uchomaji mkaa wima

- Tanuru ya mkaa ya usawa

- Tanuru ya ukarbonishaji endelevu

Ikiwa una nia ya vifaa vya kutengeneza mkaa, wasiliana nasi sasa! Tutatoa suluhisho bora kwa biashara yako ya mkaa.