Den shisha-kulmaskine er en kulformningsmaskine. Den kan forarbejde råmaterialer såsom kulpulver til firkantede eller runde hookah-kul. Vores shisha-kulpressemaskine har en produktionskapacitet på cirka 300 kg/t.

Diameterne på runde hookah-kul er normalt 30 mm, 33 mm, 34 mm, 35 mm og 40 mm, mens størrelserne på kvadratiske shisha-kul normalt er 20*20*20 mm og 25*25*25 mm. Diameter og størrelse på færdigvaren kan tilpasses efter dine behov.

Fordele ved shisha kultabletpresse

- Hookah kulmaskinen har en Høj grad af automation, med alle kontrol- og betjeningskomponenter logisk arrangeret for nem betjening.

- Den roterende hookah kulmaskine har et højt gennemløb og producerer op til 20.000 stk./h.

- Vores shisha kultabletpresse har højt tryk med et maksimalt tryk på ca. 12kn.

- Shuliy hookah kultabletpresse maskine har et integreret design, der ikke kræver installation. Desuden er den nem at vedligeholde, har ingen sliddele og har en Lang levetid.

- Diameteren og størrelsen på det færdige produkt af hookah kulfremstillingsmaskinen kan tilpasses i henhold til dine behov.

- Vores shisha-kulmaskine kan testes og justeres uden at stoppe maskinen.

Shuliy hookah kulpresse maskine til salg

Som leverandør af kulbehandlingsudstyr specialiserer vi os i produktion og salg af en bred vifte af kulbehandlingsudstyr. Blandt vores bedst sælgende shisha-kulmodeller tilbyder vi to modeller:

- Rotations hookah kul maskine

- Rustfrit stål shisha kul maskine

Hver af disse to shisha-kulpressemaskiner har deres egne unikke karakteristika, så du kan vælge den, der bedst passer til dine behov.

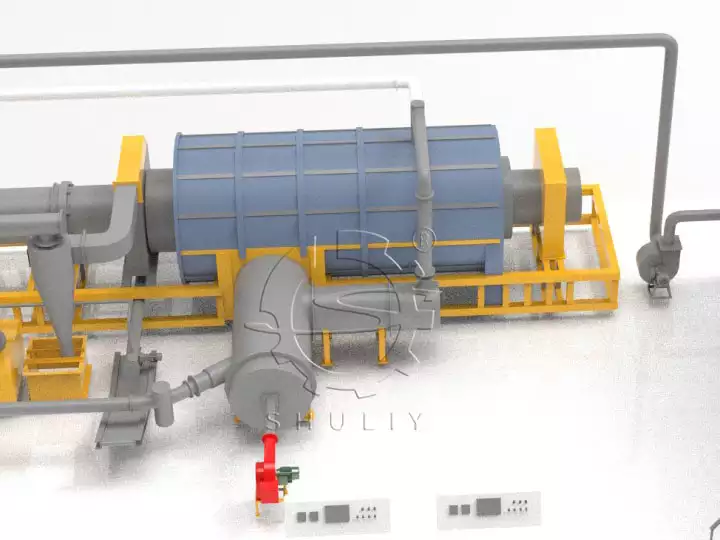

Rotations hookah kul maskine

Den industrielle roterende shisha-kulmaskine er den mest populære hookah-kulbriquette-maskine. Den er meget populær i Central- og Sydasien, Mellemøsten og andre regioner.

Formen til denne maskine er ikke en vertikal trykform, men en roterende form, hvilket sparer ventetiden ved åbning og lukning af formen under arbejdsprocessen, så output er højere.

Parametre for den roterende hookah kulpresse maskine

Parametrene for den roterende hookah-kulbriquette-maskine er som følger:

| Tryk | 12 kn |

| Kapacitet | 20000 stk/t |

| Færdig tykkelse | 8-15 mm |

| Omdrejningstakt | 3 r/min (maksimum) |

| Effekt | 7,5 kW |

| Maskinens størrelse | 800*900*1650 mm |

| Maskinvægt | 1500 kg |

Struktur af roterende shisha kulfremstillingsmaskine

Shisha-kulmaskinen består hovedsageligt af påfyldningsanordning, pulverudsugningsanordning, strømforsyning og tabletpresseenhed. Tabletpresseenheden består hovedsageligt af en øvre stempel, en midterstøbeform og en nedre stempel. Både det øvre og nedre stempel består af rullerammer og skinner.

Rustfrit stål shisha-kullemaskine

Denne hookah-kulmaskine har konstruktion i rustfrit stål, hvilket gør den meget modstandsdygtig over for korrosion og rust og sikrer en lang levetid. Designet til at levere højt tryk producerer maskinen tætte, højkvalitets kulbriquetter med høj udbytte.

Parametre for rustfrit stål hookah kulpresse maskine

Parametrene for den rustfri stål hookah-kulflagemaskine er vist i nedenstående tabel:

| Tryk | 60 tons |

| Kapacitet | 20000 stk/t |

| Effekt | 13 kW |

| Maskinens størrelse | 2500*750*2300 mm |

| Maskinvægt | 1000 kg |

Struktur af rustfrit stål tabletpresse maskine

Denne nye shisha-kulmaskine har et holdbart, korrosionsbestandigt kabinet i rustfrit stål. Dens hovedkomponenter inkluderer matertragt, kontrolpanel og ekstrusionssystem.

Råmaterialer og slutprodukt

Råmaterialer

Råmaterialerne til hookah-kul er forskellige. Det optimale og mest anvendte råmateriale til produktion af hookah-kulbriquetter er kokosnøddeskal-kulpulver. Derudover anvendes naturlige træsorter som egetræ, teak, æbletræ og kirsebærtræ.

Disse materialer sikrer produktion af højkvalitets hookah-kulbriquetter med fremragende brændeevne, hvilket gør dem perfekt egnede til brug i hookahs.

Slutprodukt

Det endelige produkt fra shisha-kulmaskinen er normalt runde eller firkantede kulblokke. Kulblokkene kan tilpasses med mønstre og tekst.

Fordele ved shisha kul

Stærkt markedspotentiale: Shisha-kul har dybe kulturelle og traditionelle rødder i Mellemøsten, med en bred brugerbase og konsekvent stabil langsigtet efterspørgsel.

Miljøfokus: Mange vælger at producere hookah-kul, da det delvist substituerer traditionelle cigaretter, reducerer tobaksforbrug og cigaretskoddsaffald og mindsker miljøpåvirkningen.

Økonomiske fordele: For kommercielle producenter giver egenproduktion af hookah-kul større kontrol over råvareomkostninger og forsyning, forbedrer produktionseffektiviteten og udvider profitmarginer.

Alsidige anvendelser: Hookah-kul strækker sig ud over brug i hookah til også at omfatte grill, opvarmning og andre områder, hvilket skaber yderligere forretningsmuligheder for producenter.

Stabil forbrugerbase: Mellemøsten og nabolandene har en betydelig, langsigtet brugerbase. Sammen med kulturelle traditioner sikrer dette en vedvarende og stabil efterspørgsel, hvilket fremmer gunstige betingelser for vedvarende virksomhedsvækst.

Fremstillingsproces af hookah kulbriketter

- Forberedelse af kulpulver: Du skal forberede kulpulver eller kulpulvermiks som råmateriale. Først karboniserer du råmaterialet ved hjælp af en karboniseringsovn. Derefter maler du den karboniserede kul ved hjælp af en grinder. Det malede kulpulver vil være finere.

- Blanding og omrøring: Bland grundigt kulpulveret med bindemidlet for at sikre jævn fordeling.

- Kompressionsformning: Fyld kulpulveret i hopperen, start maskinen, og aktiver shisha kulmaskinen for at producere hookah kulbriketter.

- Tørring af kulblokkene: Placer de formede kulblokke i batch-tørretumbleren for at tørre dem til den passende tørhedsgrad og fugtindhold.

Hvorfor vælge Shuliy som din leverandør?

- Maskinens tilpasning: Vi kan tilbyde en række tilpassede løsninger i henhold til kundernes forskellige behov, såsom hookah kulforme.

- Maskinens tilpasning: Shuliy er en velkendt producent med mange års erfaring i branchen. Vi har avanceret produktionsudstyr, et professionelt teknisk team og et komplet kvalitetsstyringssystem for at sikre, at hvert trin fra F&U til levering er pålideligt og effektivt.

- Rimelig prisfastsættelse: Shuliy hookah kulmaskine insisterer på at matche kvalitet med pris og hæver ikke blindt priser, hvilket giver kunderne mulighed for at nyde et mere omkostningseffektivt valg under forudsætning af pålidelig kvalitet.

- Perfekt efter-salgsservice: Vi tilbyder en omfattende efter-salgs garanti og professionel teknisk support for hurtigt at hjælpe kunder med at løse problemer under brugen af udstyret.

Kontakt os nu!

Udover shisha-kulmaskiner leverer vi også andet kuludstyr, såsom kulbriquette-maskiner, karboniseringsovne osv. Hvis du har behov, er du velkommen til at kontakte os, og vi giver dig gratis rådgivning!