The charcoal briquette machine can process raw materials such as carbon powder, coal powder, cow dung, grass powder, and cultured bacteria into cylindrical briquettes. The length of the briquette can range from 2.5 to 40 cm (adjustable to meet specific needs).

Our charcoal briquettes making machine boasts high efficiency, with a production capacity of 500-3000 kg/h, meeting production needs of varying scales. This makes it popular across various countries. It has been exported to Brazil, Kenya, Nigeria, and other regions. If you’re interested in this machine, please contact us for a free consultation.

숯 연탄 압출기 장점

- 숯 연탄 압축기는 매우 효율적이며, 출력은 시간당 500-3000kg| 소형 및 중형 숯 공장에서 연속 생산에 적합하게 만듭니다.

- Shuily 숯 연탄 제조기 본체는 두꺼운 강철, 손상되기 쉽지 않고 긴 수명을 자랑합니다.

- 가공된 석탄 블록은 깨지기 쉽지 않으며, 오랜 연소 시간, 그리고 a 높은 칼로리 값.

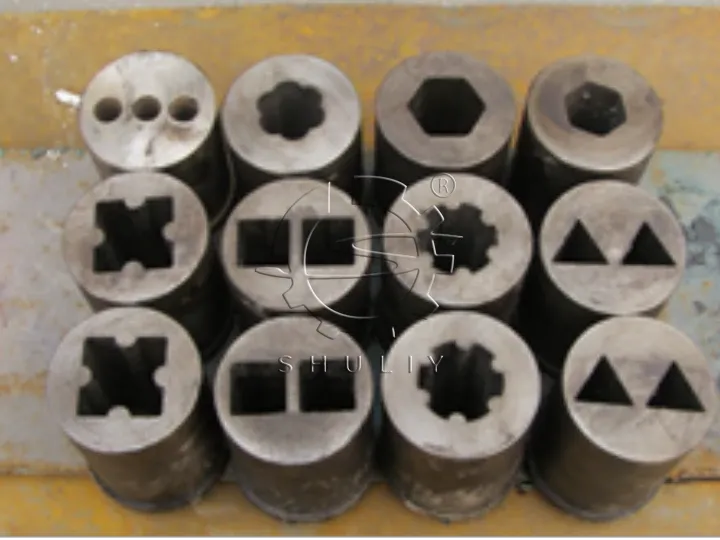

- 우리 숯 연탄 제조기는 필요에 따라 금형을 교체할 수 있으며, 석탄 블록의 모양과 크기를 조절하여 매우 유연하다.

- 그것은 사용하기 쉽다 두 사람이 완료할 수 있습니다.

숯 연탄 압축기 작동 원리

The charcoal extruder uses a screw extrusion principle to compress charcoal powder into precisely shaped briquettes.

After the charcoal powder is poured into the feed hopper, it is propelled by a screw to the briquette machine’s discharge port. From the spiral cavity to the die, the space gradually decreases. Under tremendous pressure, the desired shape is finally formed.

원료 및 완제품

원료: 탄소 분말, 석탄 분말, 소똥, 풀 분말, 배양균 등.

finished products: BBQ charcoal, industrial fuel, hookah charcoal, etc.

숯 연탄 압축기 구조

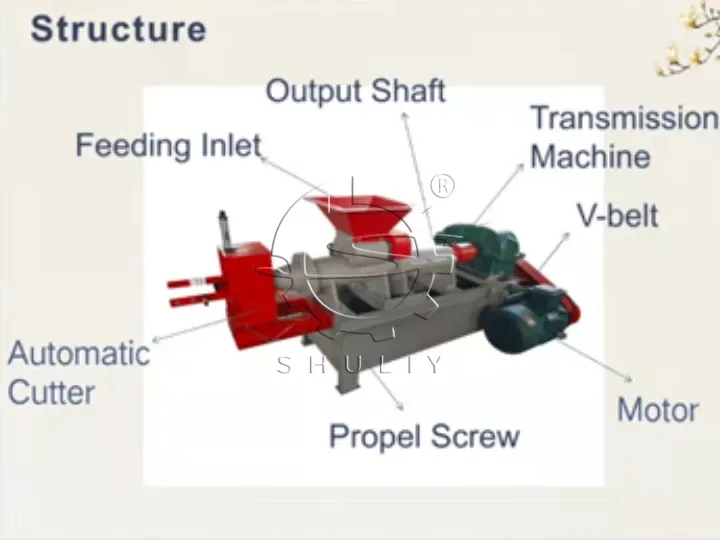

Shuliy charcoal briquette making machine is meticulously constructed, consisting primarily of motor, reducer, bearings, feed port, screw, mold, and cutter. The mold and cutter are crucial components.

- Mold: The mold controls the shape of the coal and can be replaced as needed.

- Cutter: The machine offers three types of cutters: automatic cutter, meter-counting cutter, and Shisha charcoal cutter.

숯 연탄 장비의 매개변수

As a professional supplier of charcoal processing machinery, we offer a range of charcoal briquette machines for customers to select from. The specific parameters are as follows:

| 모델 | SL-140 | SL-180 | SL-210 | SL-300 | SL-400 |

| 용량 | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

| Forming specifications (diameter) | 20-40mm | 20-60mm | 20-80mm | 20-80mm | 20-80mm |

| Spindle speed | 40-60/min | 39-60/min | 35-60/min | 35-60/min | 35-60/min |

| spiral blades | 4 | 4 | 4 | 4 | 4 |

숯 연탄 압축기 가격

When considering the charcoal briquette equipment, price is a key factor. However, the price of the briquette extruder machine is influenced by many factors, including model, output, and accessories.

Therefore, when choosing the briquette charcoal press machine, you must first clarify your needs and consider price, quality, and performance to select the most suitable machine. For more information, please contact us, and we will provide you with a detailed price list.

숯 연탄 제조기 FAQ

최종 제품의 모양이 교체 가능합니까?

예, 필요에 따라 금형만 교체하면 됩니다.

접착제가 필요합니까? 용도는 무엇인가요?

전분은 결합제 역할을 하여 숯을 더 단단하고 손상에 덜 취약하게 만들어 숯이 더 오래 탈 수 있게 합니다.

수동 작업이 얼마나 필요합니까?

두 사람.

스파이럴은 얼마나 자주 교체해야 하나요?

나사는 수리할 수 있으며, 동영상 및 온라인 지원이 제공됩니다. 약 1-2년 후에는 마모되어 사용 불가능해집니다.

커터 속도를 조절할 수 있나요?

커터는 최종 숯 길이에 따라 속도를 조절하는 유도 시스템입니다.

Shuliy 숯 연탄 제조기 성공 사례

Shuliy coal briquette machine is popular in various countries due to its excellent performance. It has been exported to Nigeria, Spain, and Slovenia. Recently, the SL-140 charcoal briquette press machine was sold to Slovenia.

The client is the head of a coal production plant. After comparing several suppliers, he ultimately chose our machine. Ten days after the machine successfully arrived in Slovenia, we received feedback from the client. He expressed his satisfaction with the machine and expressed hope for future cooperation.

지금 문의하세요!

As a leading supplier of charcoal processing equipment, we are committed to providing our customers with high-quality products. Our charcoal briquetting machines utilize advanced production technology, ensuring high efficiency and energy savings to meet our customers’ diverse production needs.

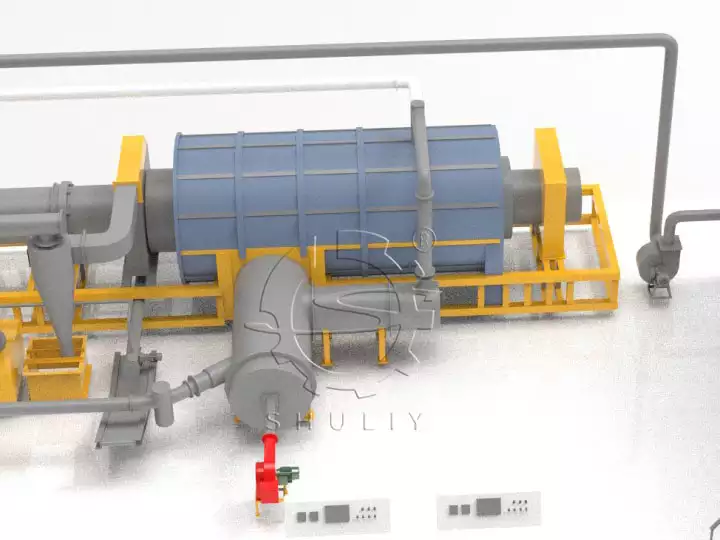

In addition to the briquette machines, we also offer vertical charcoal furnace, horizontal carbonization machine, continuous carbonization furnace, and coal dryer. If you require any assistance, please feel free to contact us!