Shuliy new charcoal making machine is an upgraded continuous carbonization machine, carbonizing sawdust, coconut shells, rice husks, etc. into quality charcoal directly by high temperature. The size of raw materials is 3-10mm, and the moisture content is <15%.

This charcoal carbonization machine has a capacity of 500-3000kg/h, and features of wide applications, customization and continuous carbonization. If you’re looking for a good carbonization furnace, it’s a good choice for you.

Features of upgraded charcoal carbonization machine

The upgraded version of the charcoal making machine is based on the traditional charcoal machine with several improvements. It increases production efficiency, reduces energy consumption, improves product quality and is more environmentally friendly.

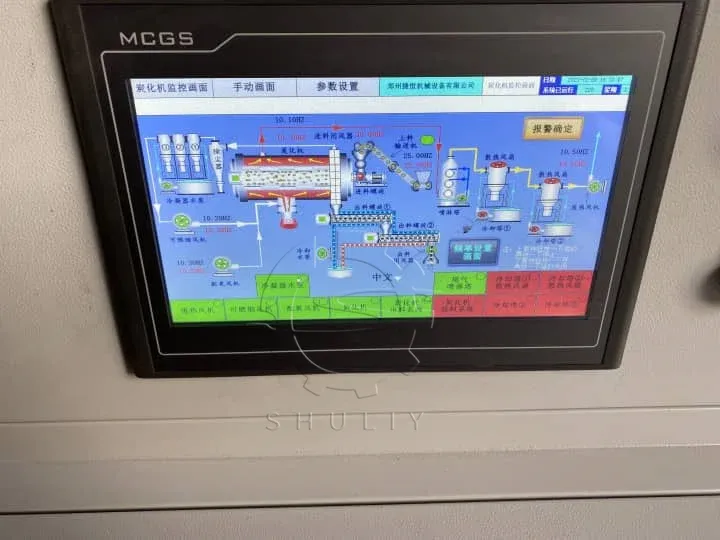

High degree of automation

- Automatic feeding system: continuous feeding can be realized, reducing manual operation and improving production efficiency.

- Automatic temperature control: through an intelligent control system, you can precisely control the charring temperature to ensure stable product quality.

- Automatic discharging system: automatically discharging the finished charcoal out of the furnace, reducing labor intensity.

High efficiency and energy-saving

- Heat recovery system: recover the heat generated during the carbonization process and use it to preheat the raw materials, reducing energy consumption.

- Adiabatic layer: the highly efficient thermal insulation material reduces heat loss and improves energy utilization.

- Optimized combustion system: the highly efficient burner to ensure full combustion and improve thermal efficiency.

Excellent environmental performance

- Flue gas purification system: purify the flue gas generated during the carbonization process to reduce the emission of pollutants.

- Good sealing: the furnace body is well sealed to prevent the leakage of harmful gases and protect the environment.

High product quality

- Precise temperature control: the precise control of carbonization temperature ensures stable charcoal quality and high fixed carbon content.

- Perfect cooling system: use a highly efficient cooling system to cool the charcoal quickly and prevent it from spontaneous combustion.

Strong adaptability

- Multifunctionality: it can process many kinds of biomass raw materials, such as wood chips, sawdust, rice husk, peanut shells and so on.

- Easy operation: simple operation and convenient maintenance.

Intelligent

- Remote monitoring: remote monitoring of equipment operation status.

- Data analysis: collect and analyze the production data to provide the basis for production optimization.

Technical parameters of new type charcoal machine

| Model | Power | Capacity | National voltage | Special voltage |

| SL-0508 | 42KW | 500KG/H | 31W | 31.5W |

| SL-0812 | 49KW | 1000KG/H | 43W | 44.5W |

| SL-1015 | 54KW | 2000KG/H | 56W | 58W |

| SL-1218 | 59KW | 3000KG/H | 80W | 83W |

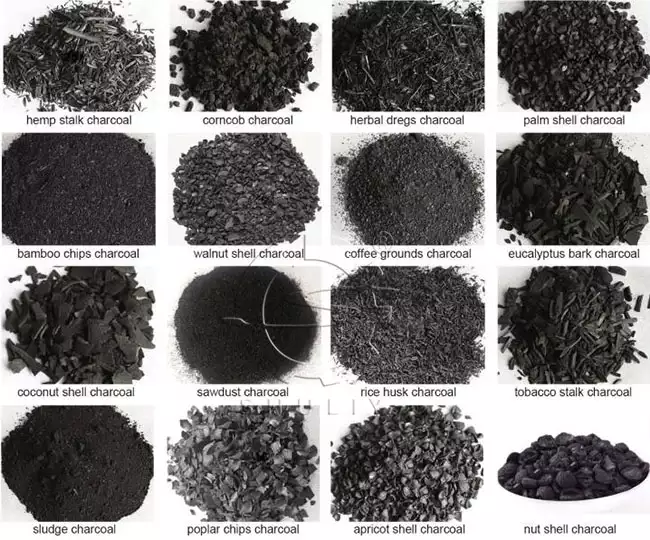

Suitable materials carbonized by Shuliy charcoal making machine

Our charcoal making kiln has a wide range of applications, such as:

- Woody materials: wood chips, sawdust, wood chunks, branches, bark, etc.

- Agricultural waste: rice husk, peanut shell, corn cobs, bagasse, etc.

- Fruit shells: coconut shells, walnut shells, apricot kernels, etc.

- Bamboo: bamboo shavings, bamboo chips, etc.

- Urban sludge, municipal sludge, industrial sludge, and others

- Municipal solid waste

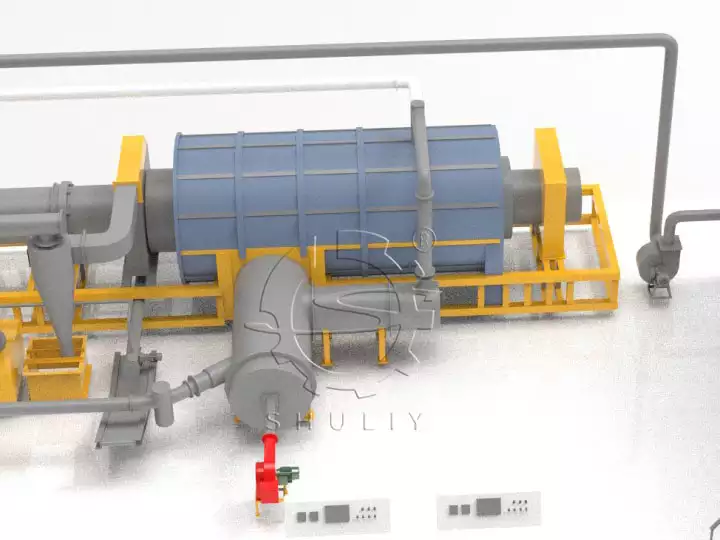

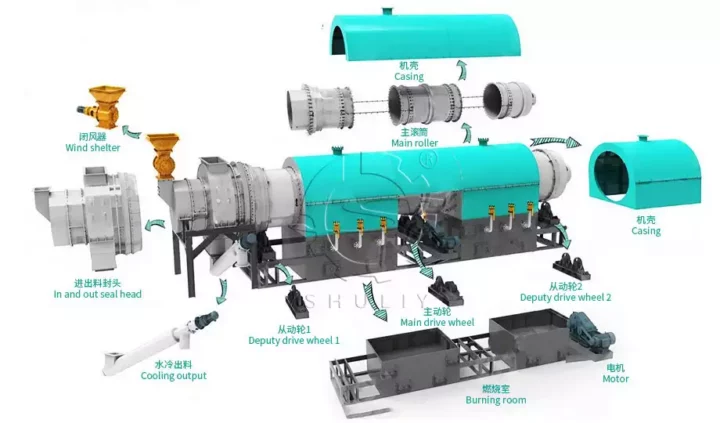

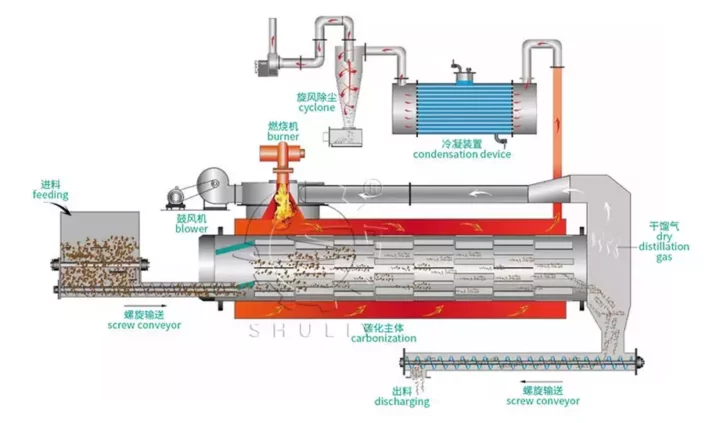

What composes this charcoal carbonization furnace?

The structure of Shuliy new type charcoal making machine includes inlet, carbonization body, outlet, etc.

Some customers have requirements before carbonizing, so, the crusher machine is equipped before the carbonization furnace.

Working flowchart of charcoal making kiln

- Feeding: the material to be carburized is fed into the furnace through the feeding device.

- Preheating: the material is preheated to remove moisture.

- Carbonization: under high-temperature conditions, the moisture and volatile matter in the material are discharged and the solid part is carbonized.

- Cooling: the charcoal is cooled to room temperature.

- Discharging: the cooled charcoal is discharged from the furnace.

How about the charcoal making machine price?

The price of Shuliy carbonizer machine will be affected by many factors, such as equipment model, production scale, automation degree, configuration, material and so on. The price of a complete set of carbonization production lines will be different according to the specific needs.

If you want to know a more accurate price, we suggest you provide the following information:

- What is your daily output requirement?

- What degree of automation do you want for the equipment?

- What are your requirements for the material of the equipment?

- Do you have a brand preference?

We will send you the best offer according to your demands.

Installation requirements

After buying the charcoal making machine, the installation is a big task. For your reference, there are some installation requirements.

- Fuel requirements

- >10 MJ/kg OS (= original substance)

- <60% DS, preferred>75% DS (dry matter)

- <30 mm

- Connection requirements

- Electricity (380V, 3 phase)

- Natural gas (CNG, LPG) 100 mbar

- Water + wastewater

- Nitrogen and compressed air

- Internet

- Foundation load capacity

- >325 kN

- Minimum space requirements

- 150 m²

- Personnel requirements

- Experience in operating relevant equipment

- Experience in handling emergencies

- Policy requirements

- Meet local environmental and other policy conditions

Related charcoal manufacturing equipment

As a professional charcoal making machine producer and manufacturer, besides this charcoal furnace, we also have:

- Vertical carbonization machine

- Horizontal charcoal furnace

- Continuous carbonization furnace

If you are interested in charcoal making equipment, contact us now! We’ll offer the best solution for your charcoal business.