Shuliy vertical charcoal furnace (hardwood charcoal making machine, lump charcoal machine) is used to convert biomass raw materials(like wood logs, sawdust briquettes, bamboo, etc) into charcoal by carrying out high-temperature carbonization treatment. It has a handling capacity of 1-3t per day.

This kind of carbonization furnace for charcoal usually works with other charcoal machines(sawdust briquette machine) to form a whole charcoal processing line. And this charcoal production line is popular in the world, and we have exported to many countries, such as Indonesia, Saudi Arabia, Myanmar, etc. If you’re interested, get in touch with us now for more details!

What materials are applied to be carbonized by the hoist charcoal furnace?

Our vertical charcoal furnace is suitable for carbonizing a wide range of raw materials, including wood (logs), branches, roots, bamboo, biomass briquettes, hardwoods, nut shells, palm shells, corn cobs, coconut shells, etc. These raw materials can be converted into high-quality charcoal products after carbonization for a wide range of uses.

Applications of carboned coal

The main use of the finished product by vertical charcoal furnace is barbecue charcoal and fuel.

Technical specifications of charcoal stove

Our vertical charcoal furnace is classified based on the inner stove diameter, and the models are shown below:

Model: SL-1000

Inner stove dia.: 1m

Height: 1.5m

Inner stove thickness: 8mm

Outer stove thickness: 6mm

Model: SL-1300

Inner stove dia.: 1.3m

Height: 1.5m

Inner stove thickness: 8mm

Outer stove thickness: 6mm

Model: SL-1500

Inner stove dia.: 1.5m

Height: 1.5m

Inner stove thickness: 8mm

Outer stove thickness: 6mm

Detailed description of SL-1500 hoist charcoal making furnace:

| Model | SL-1500 |

| Capacity | 700-800kg per time(8-10hours per time) |

| Thickness | bottom: 8mm, others: 6mm |

| Parts including | Per furnace including 2 inner furnaces, 1 lift crane,1 purification tank |

| Heating resource | Per stove needs about 50-80kg heating source Use waste wood or coal as heating source |

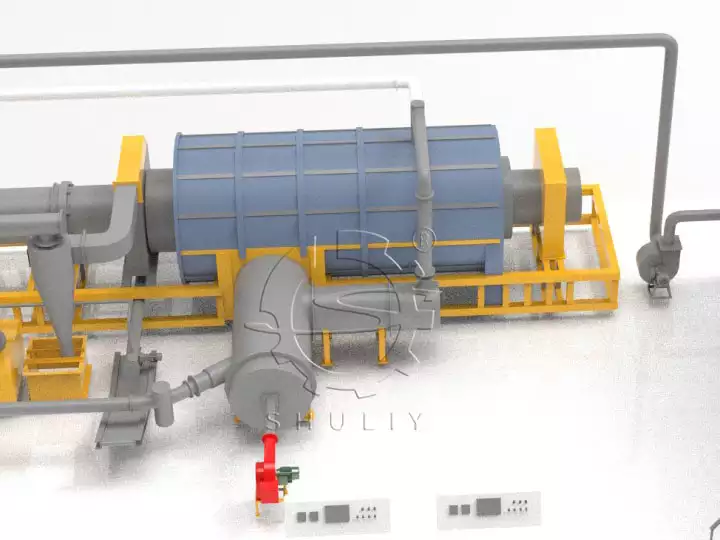

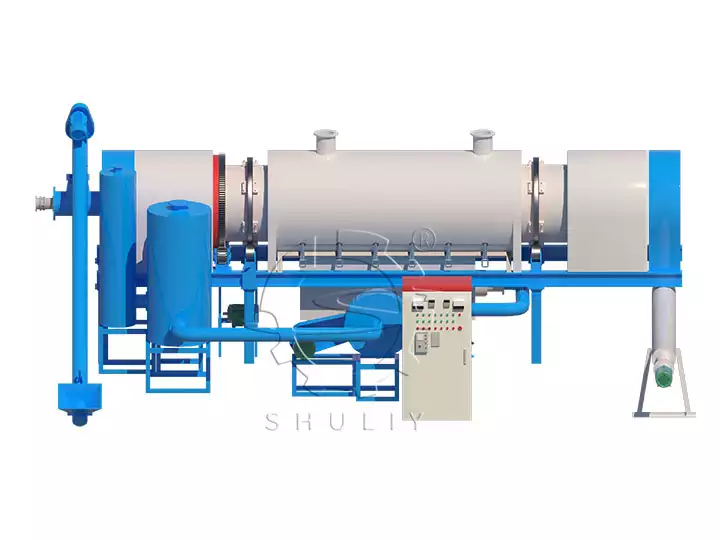

What’s the charcoal furnace design?

This air flow carbonization furnace for making charcoal consists of outer furnace, inner stoves(2 pcs), and traveling crane. The inner stove is usually equipped with a cage to hold the raw material. In addition, the charcoal furnace is equipped with filtration equipment and cooling equipment to ensure a smooth production process and safety after production.

Optional selection for charcoal furnace filter

The gas purification treatment of charcoal furnaces can usually be chosen by condenser, spray tower, cyclone and settling tank. Besides the gas purification, there is high-voltage electrostatic treatment equipment for combustion exhaust gas treatment.

Among them, for this vertical charcoal carbonization machine, it is recommended to equip condenser, build a pool and equip cooling tower.

- The condenser can effectively cool the heat in the flue gas and condense the water vapor into liquid, thus reducing the water vapor content in the flue gas.

- Building a pond and equipping it with a cooling tower further reduces the temperature of the flue gas, enhances the condensation effect, and reduces the pollution to the environment.

Integrating these methods can improve the efficiency and environmental protection of flue gas treatment and ensure the smooth running of the production process of the carbonization furnace.

How to make charcoal with the vertical charcoal furnace?

The working principle of making charcoal by using vertical charcoal furnace is airflow carbonization, which is a carbonization process through the circulation of hot air in the furnace.

The specific carbonization process is as follows:

- Use waste wood or flammable material at the bottom of the charcoal stove to provide a heat source to gradually increase the temperature.

- Before the temperature reaches 90°C, start a fire using waste material to create a large fire to provide the heat source.

- When the temperature reaches 90°C, gradually reduce the fire.

- Between 90°C and 150°C, enter the moisture removal stage and a warm fire combustion begins.

- When the temperature reaches 150°C, moisture removal begins and continues for approximately six hours, gradually increasing the fire.

- When the temperature reaches 230°C, it enters the combustion-supporting stage and produces mixed gas.

- When the temperature reaches 280°C, it enters the auto-ignition stage. The carbon monoxide gas generated by the carbonization furnace can be recycled and burned by itself without the need for an external heat source. At this time, the door at the bottom of the furnace is closed.

- The door at the bottom of the furnace can be optionally closed or opened during the whole process.

About the carbonization process, you should know The maximum temperature inside the furnace can reach 500°C. The best carbon formation effect requires 14 hours of combustion in the carbonization furnace, followed by more than 10 hours of cooling time.

The pipes in the charcoal furnace mainly serve for gas circulation, combustion and filtration.

Advantages of sawdust charcoal making machine

- Gas recycling: Gas can be recycled (after one hour) without adding materials all the time, saving manpower;

- Two inner stoves: We provide two inner stoves, and the production of another can be continued during the cooling process, saving time;

- Safe to use: High-temperature rubber is located internal area, not easy to collapse;

- If a strict environment is required, the fuel can be used;

- Traveling crane load capacity of more than two tons.

Do you know the carbonization furnace price?

Our vertical charcoal furnace price varies between thousands and thousands of dollars. The detailed price is composed of your demands, gas purification system, shipment costs, after-sales services and others.

Taking this vertical charcoal making furnace as an example, SL-1500 is more valuable than SL-1300. f you have a powerful financial ability and want to produce charcoal in large batches, SL-1500 is a better choice for you. This is all to be decided based on your actual situation. You can contact us directly for a suitable charcoal making solution.

Related charcoal making machines

We also have horizontal charcoal making machine and continuous charcoal furnace for sale, used for high-quality coal production. Besides, if you want to shaped charcoal making, after vertical charcoal furnace, we also have machines for your subsequent processing, like hammer mill(for charcoal), wheel mill grinder(for charcoal powder) and charcoal briquette extruder machine(for shaped charcoal briquettes).

If you’re interested, welcome to contact me for more machine details!