Shuliy charcoal briquette extruder machine is popular worldwide for its excellent performance and has been exported to countries such as Nigeria and Spain.

Recently, the SL-140 charcoal briquetting machine was exported to Slovenia again, providing a highly efficient and stable production solution for local coal production companies.

Customer needs & our solution

The client, a coal production plant in Slovenia, produces coal briquettes and charcoal products. He required a machine with a 500k/h output and adjustable briquette sizes. Furthermore, He required the machine to be stable and easy to operate, facilitating ongoing maintenance and staff training.

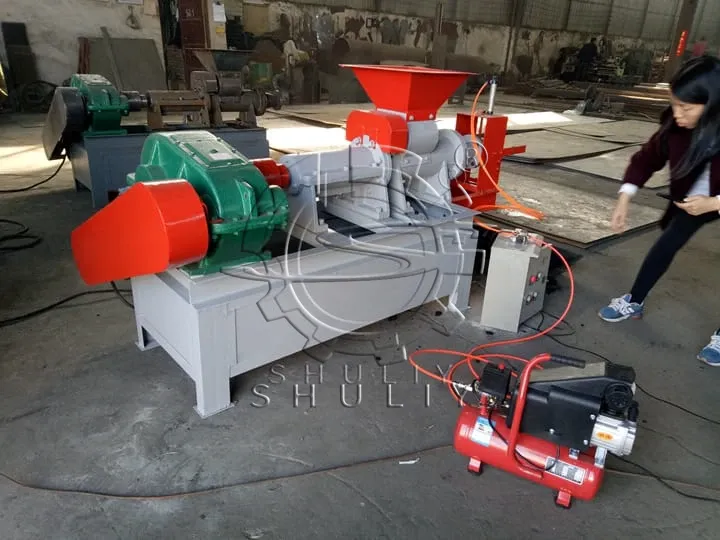

After discussing the situation, we recommended the SL-140 charcoal briquette machine based on their needs. This machine can process a variety of raw materials, including pulverized charcoal, pulverized coal, and grass powder, and boasts a production capacity of 500kg/h.

Equipment highlights

- Compatible with a variety of raw materials: It can process pulverized carbon, pulverized coal, and cultured bacteria, offering greater flexibility in raw material utilization.

- Various forming specifications: The length and diameter of the cylindrical charcoal rods can be adjusted to meet diverse customer needs.

- High capacity: This charcoal briquette extruder machine has a capacity of 500kg/h, it suitable for small and medium-sized businesses, improving overall production efficiency.

- Long service life: The body of this charcoal briquette machine is constructed of thickened steel, making it durable and resistant to damage.

- Easy operation: Shuliy charcoal briquette press machine is simple to operate, requiring only two people to complete the task.

Customer feedback

To protect the machine from damage during transportation, we packed it in wooden boxes. Ten days after the charcoal briquette extruder machine arrived in Slovenia, the customer reported that the machines were operating stably with excellent molding results, significantly boosting production output.

He particularly noted Shuliy’s clear installation instructions and prompt after-sales follow-up, which made the entire cooperation process smooth and efficient. He also expressed their expectation to continue working with Shuliy in the future.

Conclusion

This partnership demonstrates Shuliy’s strength in charcoal processing equipment and provides Slovenian customers with more efficient and environmentally friendly production solutions.

We consistently adhere to the principle of “quality first, customer first,” providing customized solutions and professional technical support to customers worldwide. If you need the charcoal briquette extruder machine or other charcoal processing equipment, please feel free to contact us!