Our bamboo charcoal making machine is good design equipment used to carbonize bamboo chips, bamboo segments, bamboo pellets, etc into bamboo charcoal, commonly as fuel for industrial uses. This bamboo charcoal machine has a processing capacity of 1-3t per day. If you want bigger capacity, we also have the suitable solution to meet your demands.

Besides, our bamboo charcoal kiln has the advantages of multiple choices, high convert ratio and cost-effectiveness, thus popular around the world. The bamboo activated charcoal machine has great performance in handling various bamboo through a series of processes(like preparation, carbonization) for high-quality bamboo charcoal.

Process to make bamboo charcoal

Bamboo charcoal production is relatively simple but requires patience and skill. Below are the general steps of bamboo charcoal production by bamboo charcoal making machine:

Bamboo preparation

Select good quality bamboo, preferably mature but not aged.

Cut the bamboo into appropriate-sized segments and clean the surface of impurities and soil.

Carbonization process

Put the bamboo segments into the bamboo carbonization stove, which is usually controlled at a temperature between 400°C and 800°C.

During the charring process, the water, volatiles and unstable organic compounds in the bamboo material are completely thermally decomposed to form bamboo charcoal with good adsorption properties.

Cooling and collection

After carbonization, the bamboo charcoal is removed from the carbonization furnace and placed in a well-ventilated area for cooling.

The cooled bamboo charcoal is screened and graded to remove impurities and incomplete pieces.

Packaging and storage

Pack the bamboo charcoal as needed, usually in plastic bags or cardboard boxes.

Store in a dry and ventilated place, avoiding humidity and direct sunlight.

Raw materials used for bamboo charcoal making

Our bamboo charcoal making machine can use different bamboo raw materials to make charcoal. According to the shape of bamboo, the specification size of each type is roughly as follows:

- Bamboo tube: diameter 2-6cm, length 5-15cm

- Bamboo sheet: length 5-15cm, width 3-5cm

- Bamboo chips: 2-10cm

- Bamboo pellets: 3-5mm; 1-3mm

- Bamboo sawdust: diameter 100 mesh>1mm; diameter 100 mesh <1mm or less

All of the above bamboo raw materials can be used to make bamboo charcoal, including but not limited to these.

The above is the general process of bamboo charcoal production with our bamboo carbonization machine, the specific operation steps and parameter settings may vary according to different production equipment and process.

Shuliy bamboo charcoal making machine for sale

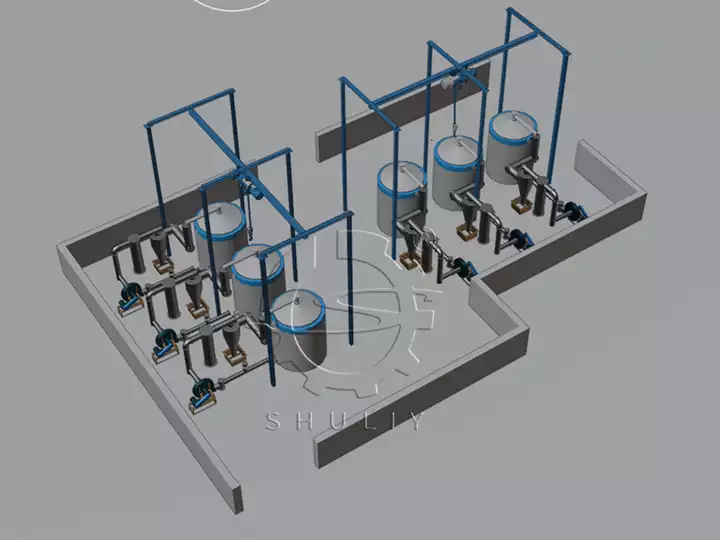

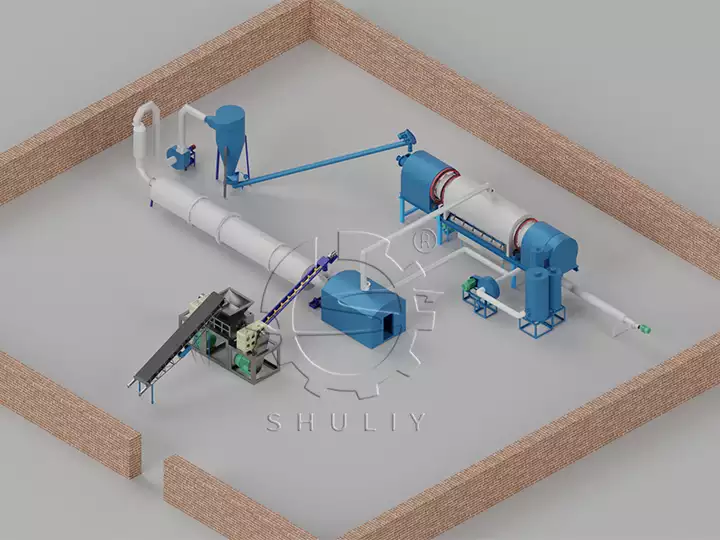

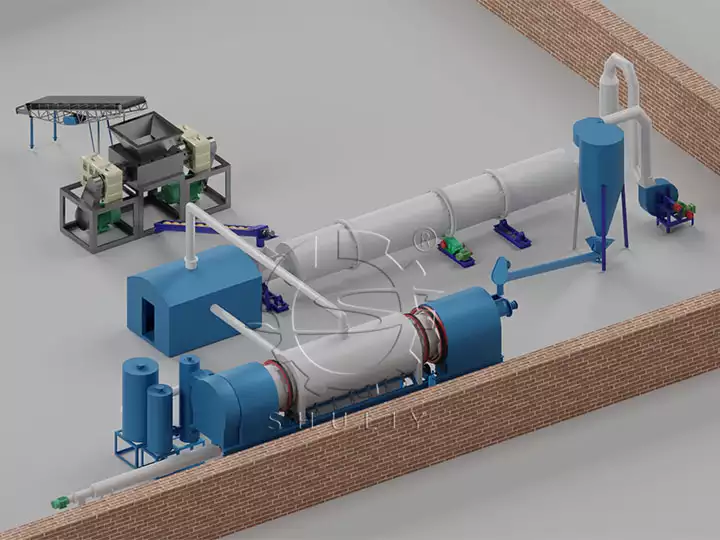

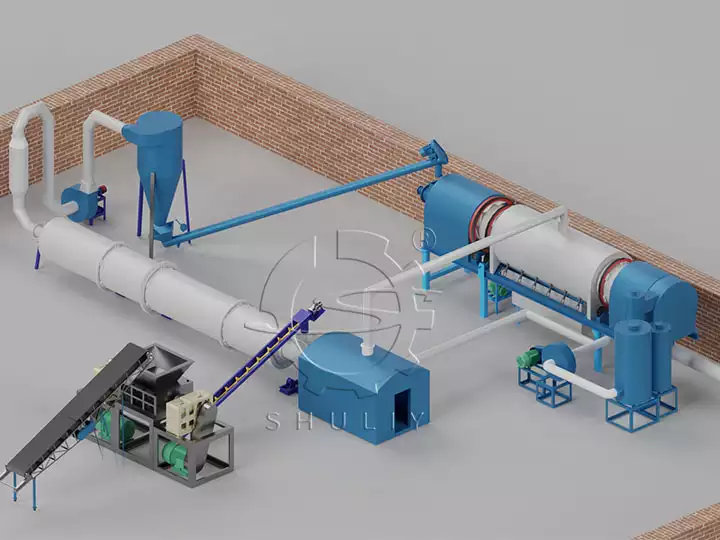

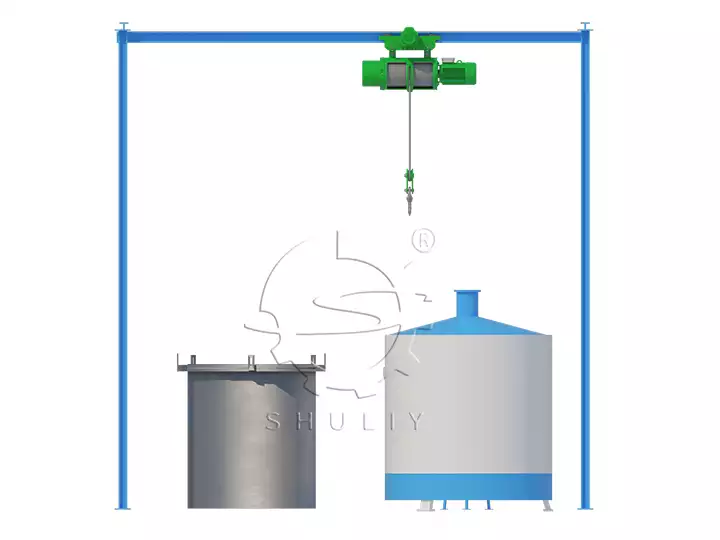

As mentioned the equipment that can go into bamboo charcoal production is called charcoal furnace, as a professional charcoal machine manufacturer, we have 2 charcoal kilns for you to choose from.

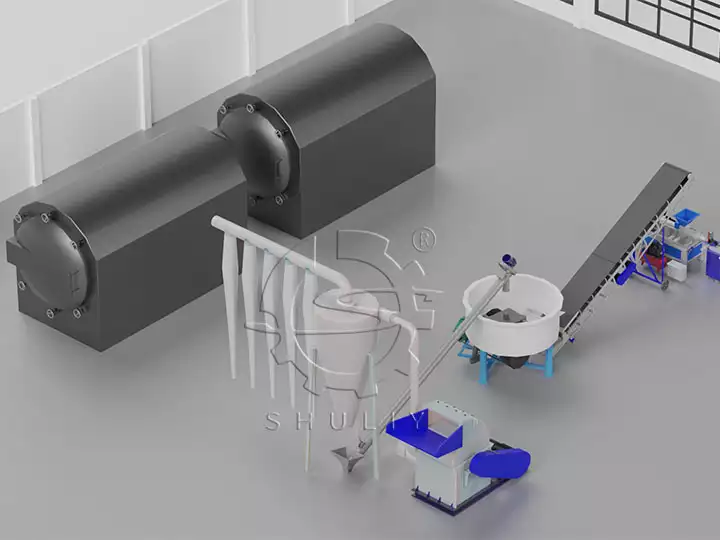

They’re respectively horizontal charcoal furnace and hoisting charcoal kiln. Both can carbonize bamboo raw materials into high-quality bamboo charcoal.

Horizontal charcoal oven show

Vertical charcoal kiln show

Advantages of bamboo charcoal machine

As mentioned at the beginning, our bamboo charcoal machines have strengths of multiple options, high conversion rates, and cost-effectiveness, as well as customization, see below for specifics.

- Multiple options: we have 2 types of bamboo charcoal kilns for choice, horizontal & vertical carbonization machines.

- High conversion ratio: our bamboo carbonization machine usually has a conversion ratio of 3:1, i.e. 3t of raw material can produce 1t charcoal.

- Cost-effectiveness: we’re integrated into manufacturing and trading, so our bamboo charcoal making machine has good quality, at the same time, has a good price, compared to other suppliers.

- Customization: when you buy bamboo carbonization oven, we can customize the machine to meet your demands, such as voltage, gas filter processing system, ignition method, etc.

How about bamboo charcoal making machine price?

Shuliy bamboo charcoal machine price starts $5000, but our bamboo carbonization machine has different models. Different configurations have different prices, it depends on your needs.

You should know the above price is just an estimated price, if you want an exact price, contact me now!

Successful application of bamboo charcoal making machine in the world

Around the world, our bamboo charcoal making machines are widely used to produce high-quality bamboo charcoal products. With the Shuliy bamboo charcoal machine, producers around the world can make full use of local resources to convert bamboo into high-quality bamboo charcoal to meet the market demand.

Whether in Asia, Africa or elsewhere, bamboo charcoal kilns have demonstrated their significant advantages in improving productivity and product quality.

Contact us today for more machine details!

If you are also interested in bamboo charcoal making machine, please feel free to contact us. We will provide you with detailed information about the machine and customize a solution that best suits your production needs. Act now to start your bamboo charcoal production journey!