The coal briquette making machine is a carbon forming machine that processes raw materials such as carbon powder and coal powder into spherical carbon briquettes. Its working principle is to use the high pressure between the forming rollers to squeeze materials such as coal powder into shape.

Our charcoal briquette machine boasts exceptional efficiency with a capacity of 2-40t/h. The diameter of the finished product is 30-60mm, and it can be customized according to your needs. Are you interested in the coal ball briquette machine? If so, contact us immediately for a free consultation!

Excellent features of Shuliy coal briquette press machine

- Multiple models available: Shuliy offers a variety of coal briquette machine models with production capacities ranging from 2 to 40 tons/hour to meet the production needs of various businesses.

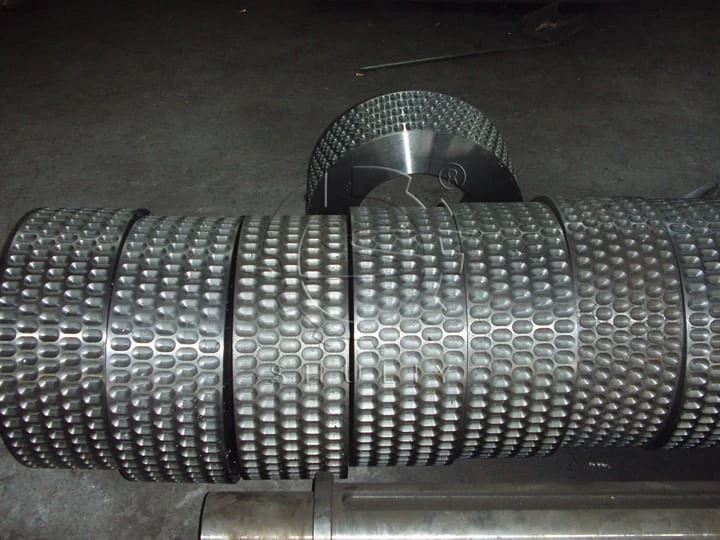

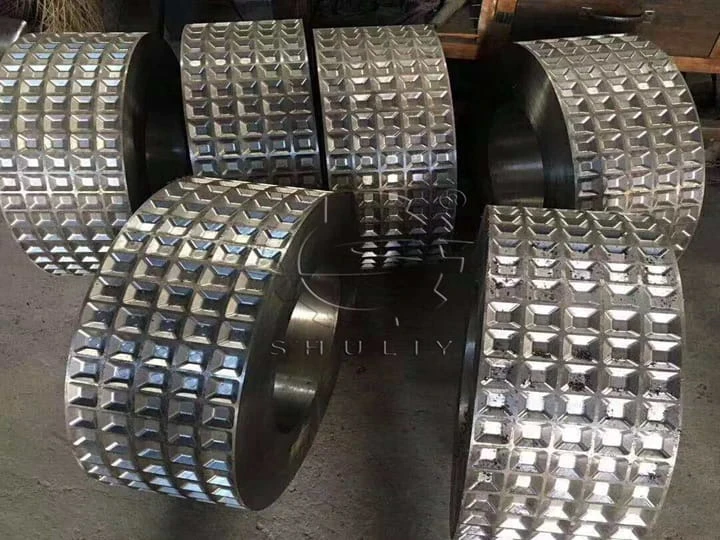

- Long service life: Our machine utilizes high-quality 65Mn rollers, which are wear-resistant and have a long lifespan, reducing maintenance costs.

- Efficient energy consumption: Each model is equipped with motors of different power to achieve high voltage and low energy consumption.

- Excellent forming: The briquettes produced by this machine are high-density and beautifully shaped, making them easy to transport and store while reducing dust and waste.

- Customizable diameter: Our coal briquette machines produce briquettes with diameters ranging from 30 to 60 mm, and we support custom sizes.

- Complete service support: Shuliy provides customers with comprehensive technical guidance, parts supply, and after-sales service to ensure the long-term and stable operation of our equipment.

Main parts of charcoal ball press machine

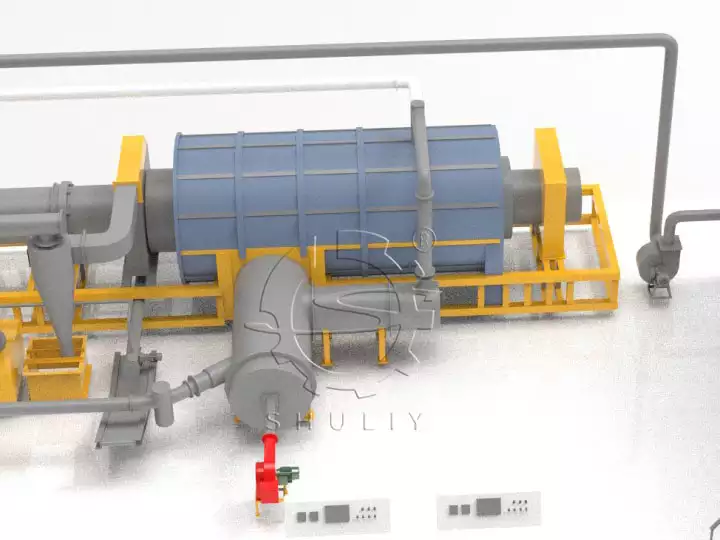

Shuliy coal briquette making machine mainly consists of feeding part, transmission part, forming part, hydraulic system, and pressure-bearing inclined iron structure. These components work together to achieve efficient pressing and forming of materials such as coal powder and carbon powder.

- Feeding part: This part can feed charcoal powder, coal dust, coke powder, mineral powder, sludge, and other loose materials into the briquetting machine stably and quantitatively.

- Transmission part: The motor power is transmitted to the pressure roller through the V-belt, reducer, and open gear, so that the two rollers rotate synchronously in opposite directions.

- Molding part: It can complete the high-pressure pressing and forming of the material, and the size and shape of the finished product can be changed by replacing the pressing roller mold.

- Hydraulic system: The function of this part is to provide and stabilize forming pressure, drive the floating rollers, and automatically adjust during pressure fluctuations.

Working principle of coal briquette making machine

- Power transmission: The main motor drives the V-belt, which in turn transmits power to the two rollers through a reducer and drive shaft, causing them to rotate synchronously and in opposite directions.

- Material supply: Mixed materials such as pulverized coal and coal slurry from the storage bin are steadily fed into the hopper via a metering device to ensure uniform feeding.

- Flow control: The hopper baffle is adjusted to control the flow and position of the material entering the rollers, ensuring accurate delivery to the roller centerline.

- High-pressure forming: When the material enters the space between the two rollers, it is squeezed under high pressure, forming a dense, uniform ball.

Models and parameters of coal briquette equipment

In order to meet the production needs of different customers, we provide a variety of models of coal briquette machines. The following are the main technical parameters of Shuliy coal briquette making machine:

| Model | SL-290 | SL-360 | SL-400 | SL-500 | SL-650 | SL-750 | SL-850 | SL-1200 |

| Capacity(t/h) | 2-3 | 4 | 6 | 10 | 14 | 17 | 20 | 40 |

| Power(kw) | 5.5-7.5 | 7.5 | 11-15 | 18.5-22 | 30 | 37 | 45 | 75 |

| Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

| Finished product diameter(mm) | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 |

Raw materials and finished products

Raw materials: The primary materials for the coal briquette making machine typically include carbon powder, coal dust, mineral powder, etc. Generally, the moisture content of the raw materials should preferably be more than 8% to 10%.

Final product: The finished coal typically takes the form of conventional spherical, pillow-shaped, or rugby ball-shaped pieces. The shape and size of the final product can be customized according to your needs.

Price of charcoal ball press machine

The price of the coal briquette making machine is not fixed; it’s affected by a variety of factors, including model, production capacity, and optional features. The final price will depend on your specific needs.

However, when choosing the BBQ charcoal ball making machine, quality is equally important alongside price. If you’re looking for a coal briquette machine, contact us today. We’ll provide you with the best quality equipment at the most reasonable price!

FAQ of BBQ coal briquette machine

What raw materials can this machine be used for?

The commonly used raw materials are carbon powder and coal powder.

Can the dimensions of the coal briquette machine be customised?

It can be customised to suit your requirements.

What are the shapes of the finished products?

Conventional spherical, pillow-shaped core, rugby ball-shaped.

What is the moisture content of the finished product?

About 20%.

What are the dimensions of a regular sphere?

5*3cm.

Why choose Shuliy as your preferred supplier?

As a specialist manufacturer of coal briquetting presses, Shuliy not only supplies high-quality equipment but also provides customised services and technical support to our clients.

Moreover, our equipment range is comprehensive. Beyond coal briquette making machine, we also offer charcoal briquette extruder machine, shisha charcoal machine, carbonization furnace, and more. If you are seeking coal processing equipment, please contact us for further details!