The charcoal extruder machine is a device that uses high pressure to extrude powdered materials, such as coal and charcoal, into briquettes. It is widely used in the barbecue fuel, boiler fuel, and biomass fuel processing industries. Choosing the right charcoal briquette machine can not only increase output but also reduce production costs.

Understanding working principle

Understanding how a charcoal briquette making machine works is the first step in purchasing one. The charcoal extruder machine uses a screw propulsion system and high-pressure extrusion to press various raw materials into shape within a mold. Commonly processed raw materials include:

- Coal powder

- Charcoal powder

- Sawdust charcoal powder

- Coconut shell charcoal powder

- Biomass charcoal powder

Selecting model based on production demand

Different users have different production capacity requirements. Choosing the right model based on production capacity is one of the most important factors when selecting a briquette machine. Selecting the charcoal extruder machine with the appropriate production capacity can improve efficiency and avoid wasting production capacity.

| Production requirements | Recommended models | Target audience |

| 300-500kg/h | Small charcoal briquette machine | Entrepreneurs, small processing plants |

| 600-1000kg/h | Medium-sized charcoal briquette machine | Medium-sized processing enterprises |

| 1000-3000kg/h | Large charcoal briquette machine/production line | Industrialized production |

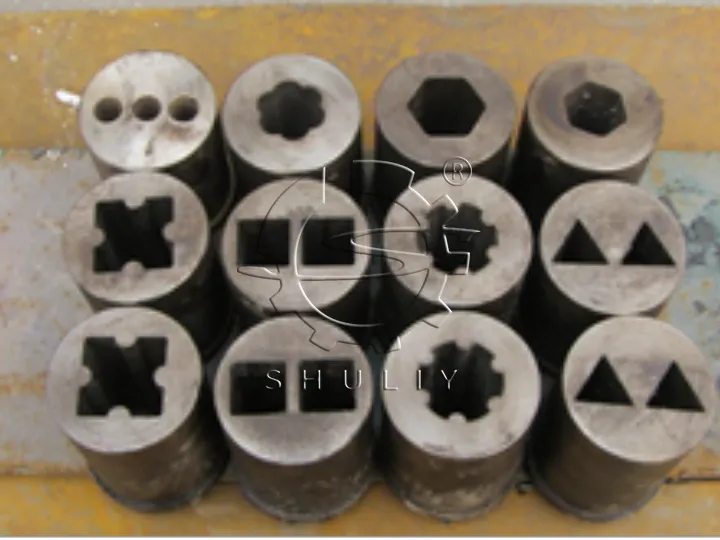

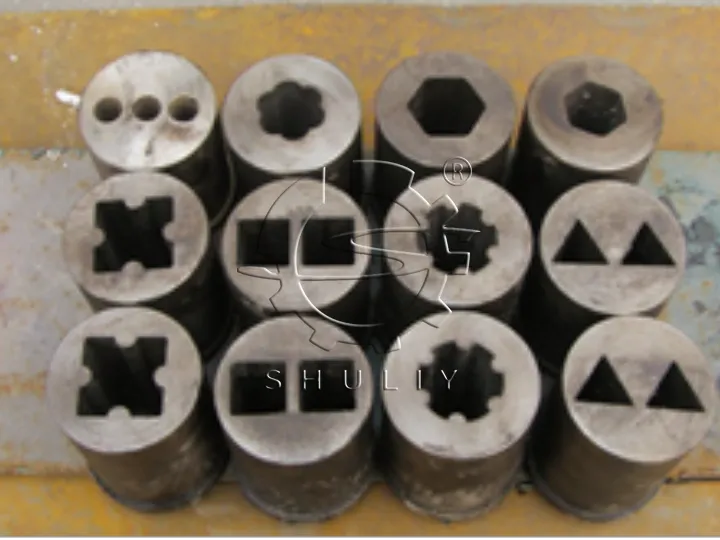

Pay attention to molding effect and mold type

The mold used in a charcoal briquetting machine determines the shape and market applicability of the coal briquettes. Common shapes include:

- Hexagonal hollow coal briquettes

- Square coal briquettes

- Cylindrical coal briquettes

- Perforated coal briquettes

When selecting the charcoal extruder machine, it should be confirmed whether the equipment supports mold replacement to meet different market demands.

Equipment materials and durability

When choosing the charcoal briquette extruder machine, the quality of the machine is paramount. A high-quality charcoal extruder machine typically features:

- Thickened, wear-resistant screws

- High-strength alloy molds

- A stable motor configuration

While high-quality equipment requires a slightly higher initial investment, it offers lower maintenance costs and a longer service life.

Contact us for a free consultation!

Choosing the charcoal briquette press machine requires comprehensive consideration of output, forming effect, and equipment quality. Selecting the right equipment not only ensures stable production of high-quality charcoal briquettes but also helps businesses quickly enter the fuel market and achieve long-term profitability.

If you are looking for a suitable charcoal extruder machine or a complete production line, please contact us for professional solutions and quotations!