Our sawdust charcoal making machine is used to turn wood sawdust into charcoal by continuous charring at high temperatures. Our sawdust carbonization furnace has a capacity of 800-1000kg/h. Due to using the continuous charcoal making machine, the raw materials, i.e., sawdust have requirements of size ≤5cm and moisture ≤20.

As a professional charcoal machine manufacturer, we provide two solutions to make sawdust charcoal for profit. Are you interested? If yes, contact us now for more details!

Solution to make charcoal from sawdust

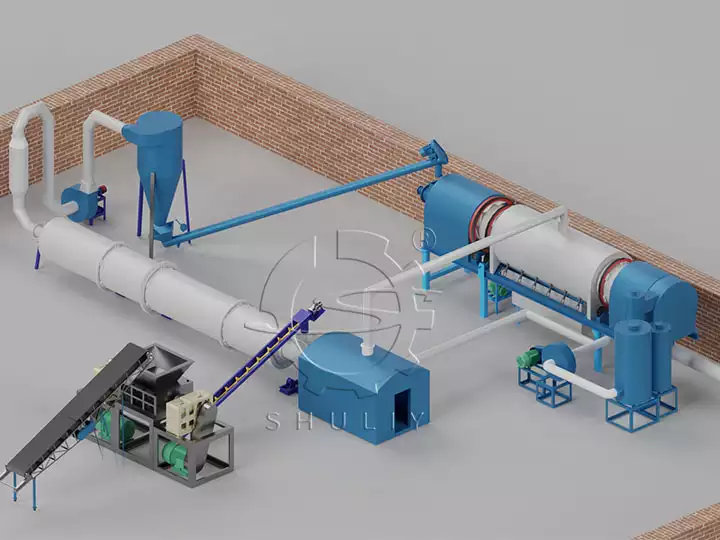

Depending on the charcoal manufacturing ways, we can have two different ways of processing sawdust through the sawdust charcoal making machine, as described in the following display:

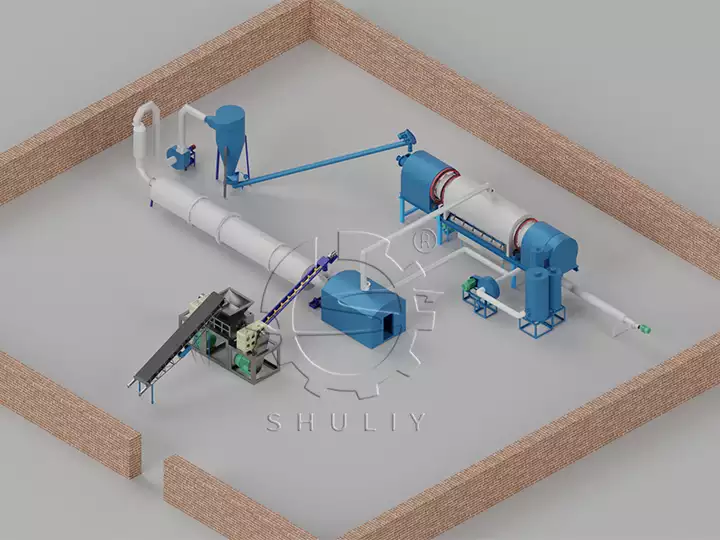

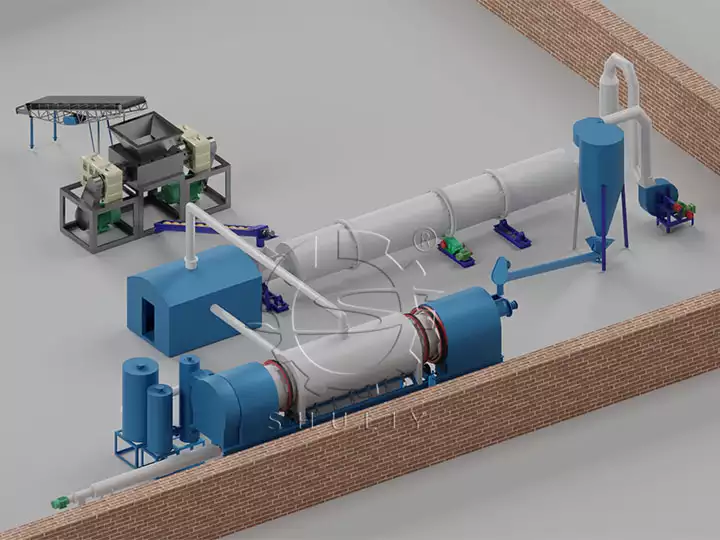

Solution 1: carbonizing and briquetting

Because our raw material is sawdust, this thinking mode of making sawdust charcoal is to carbonize it before briquetting. This solution is:

- Choose the right sawdust charcoal making machine to carbonize the sawdust, then cool it and collect it.

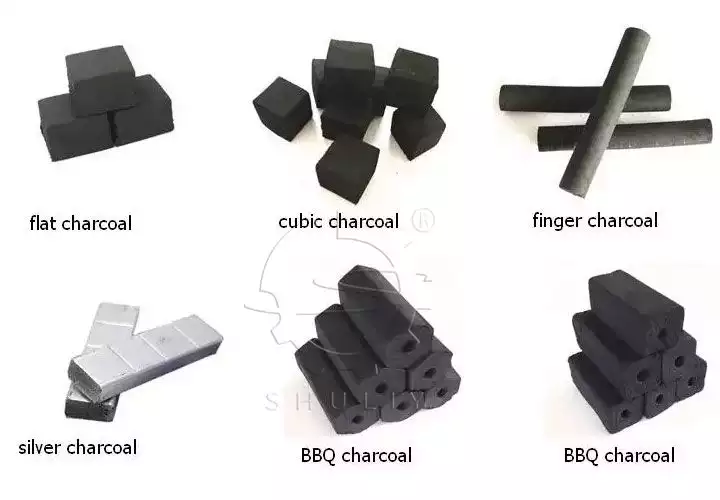

- Next, the sawdust charcoal is made in various forms using a suitable charcoal briquette press and the final shape of the charcoal depends on your needs.

Final products are shown below:

Solution 2: briquetting and charring

This way is to directly produce sawdust briquette charcoal. Briquette raw material sawdust biomass into biomass briquettes, then carbonization, the operation steps are as follows:

- The biomass feedstock is put into the sawdust briquette making machine, compressed into sticks by high temperature and pressure, and then dried and collected.

- Then, the biomass rods are carbonized in a sawdust charcoal machine, and the final product is sawdust briquette charcoal, which can be as fuel for sale.

The final products of each step are shown below:

Sawdust charcoal making machines used in coal making process

Through the above two ways to make sawdust charcoal, the machine for making charcoal from sawdust is different with different solutions.

Sawdust charcoal making machine used in Solution 1

The small charcoal making machine is for biomass charcoal, consisting of continuous charcoal kiln and charcoal briquette extruder.

The continuous carbonization furnace is used to carbonize sawdust and the charcoal briquette extruder is responsible for molding sawdust charcoal into charcoal with expected shapes.

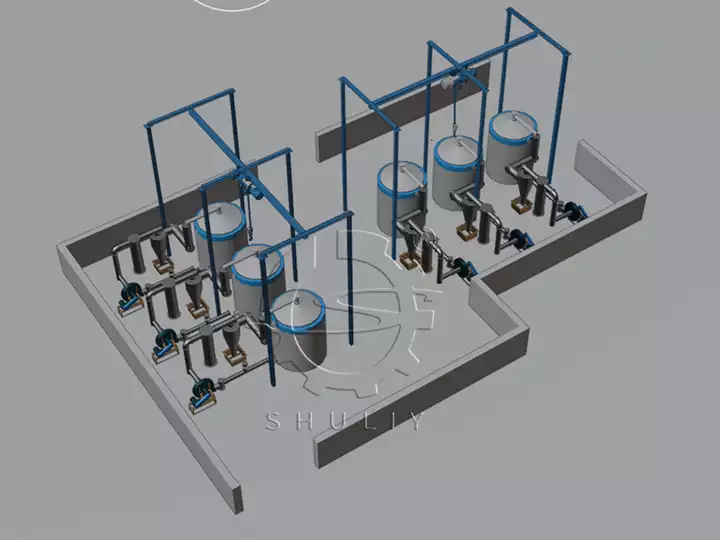

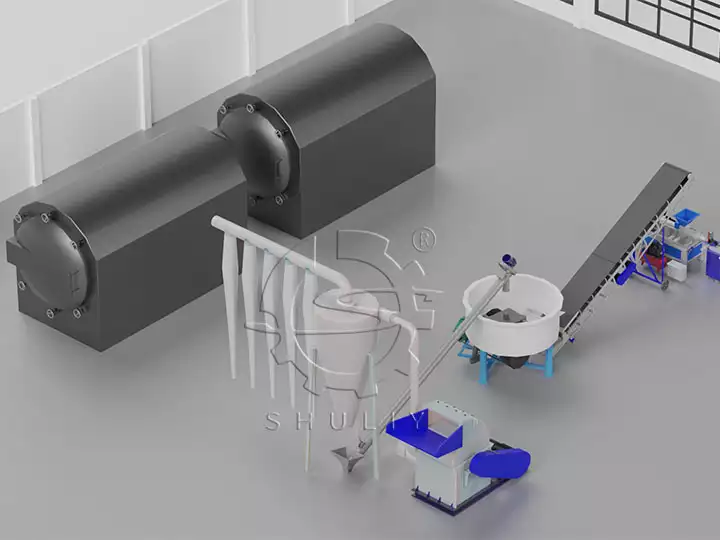

Sawdsut biomass charcoal machine used in Solution 2

This way uses biomass briquette machine and sawdust briquette charcoal making machine(i.e. vertical charcoal furnace or horizontal charcoal oven).

Our sawdust briquette machine compresses biomass into briquettes and the vertical carbonization machine is used to carbonize them into sawdust briquette charcoal.

Advantages of sawdust charcoal making machine

- High efficiency and energy saving: Adopting advanced carbonization technology, the sawdust charcoal machine can realize high efficiency and energy saving production process, maximize production efficiency and reduce energy consumption.

- Multifunctionality: It is suitable for various raw materials, such as wood chips, cassava residue, etc. It has strong applicability and flexibility, and can produce high-quality charcoal products according to different raw materials to meet the market demand.

- Environmental protection and energy saving: The sawdust charcoal production process reduces the emission of waste gas and wastewater, and adopts resource recycling technology, which meets the requirements of environmental protection and is conducive to sustainable development.

- Stable charcoal quality: Our charcoal furnace uses advanced production technology, which can procude stable coal products with high density and strength, favored by customers.

Benefits of making charcoal by sawdust biomass

There are many benefits of utilizing sawdust biomass to make charcoal:

- Abundant resources: sawdust and other biomass wastes are widely available, and the use of these wastes to make charcoal can fully utilize resources and reduce costs.

- Efficient utilization: Sawdust and other biomass wastes are used as raw materials, and through the biomass charring technology, efficient utilization can be achieved, transforming the wastes into valuable charcoal products.

- Excellent product quality: Charcoal made from sawdust with sawdust charcoal making machine has high density, high calorific value, long burning time and stable quality, which is suitable for a variety of application scenarios.

- Remarkable economic benefits: Charcoal is a product widely used in life and industry, and by utilizing sawdust biomass to manufacture charcoal, stable economic returns can be created.

- Waste reduction: Utilizing sawdust and other waste materials to manufacture charcoal effectively reduces the accumulation of waste and plays a positive role in improving the environment.

Utilizing sawdust biomass to manufacture charcoal by biomass charcoal making machine can not only effectively solve the problems of resource waste and environmental pollution, but also create economic value and promote sustainable development.

Profitable charcoal products from sawdust

The ultimate goal of charcoal production using sawdust charcoal making machine is definitely to make a profit, so here are some of the popular charcoal shapes that can be produced with sawdust in the global market.

Interested? Contact us for more details!

If your answer is YES, get in touch with us now! Tell us your demands, such as the final charcoal shape, budget, etc., and we’ll provide the best solution to make charcoal.