The coconut shell charcoal making machine is equipment especially to turn coconut shells and carbon-containing raw materials into charcoal by high-temperature carbonization.

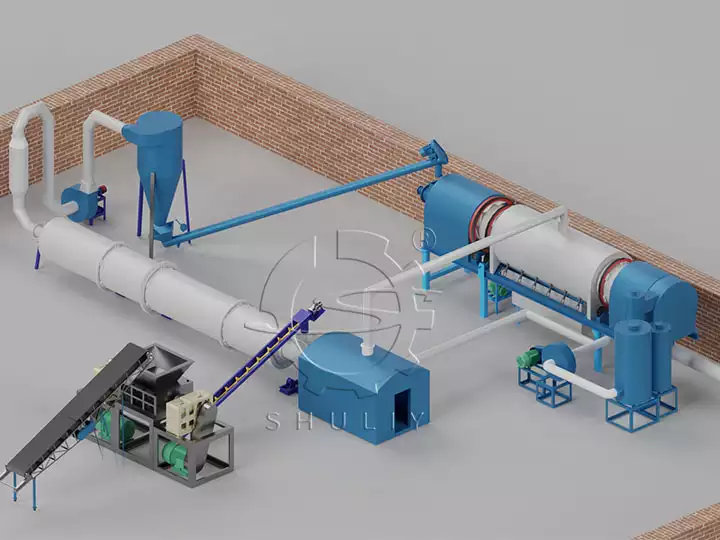

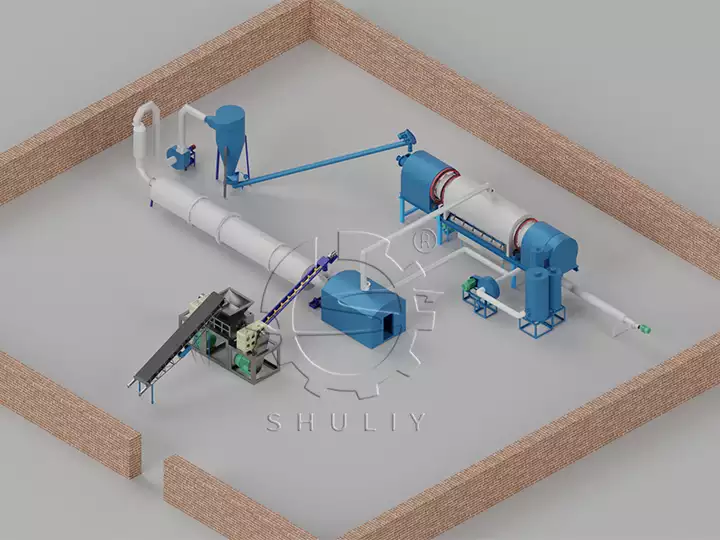

As a professional charcoal machine manufacturer and supplier, we have 2 types of coconut charcoal machines suitable for coconut shell charcoal making, both with good performance, long service life and environmental protection.

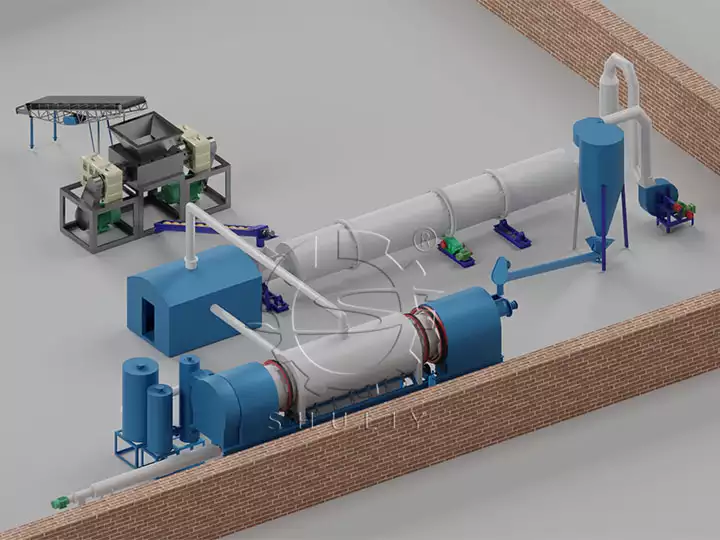

Steps to make coconut shell charcoal

Coconut shell charcoal is very popular in the world, and it’s necessary to know the coconut shell charcoal making process. But do you know how to make coconut shell charcoal, show details below:

Step 1: Preparation of raw material

Firstly, the coconut shells are collected, cleaned and treated to remove impurities and moisture for subsequent carbonization.

Step 2: Crushing

The clean coconut shells are fed into a shredder for pulverization. This step is designed to break the coir into small pieces for the subsequent charring process.

Step 3: Drying

The pulverized coconut shell pellets are put into a rotary dryer for drying to remove the moisture from the coconut shells. During the drying process, the temperature and humidity are controlled to ensure that the moisture content of the coir is minimized.

Step 4: Carbonization

The treated coconut shells are put into the coconut shell charcoal making machine for carbonization. In the carbonization furnace, the coconut shell is heated at high temperature and in an oxygen-poor environment, and gradually loses moisture and volatile substances, and is finally transformed into coconut shell charcoal.

Step 5: Cooling and curing

After carbonization, the coconut shell charcoal needs to be cooled and cured to achieve the proper hardness and density. Cooling equipment or natural air cooling is usually used to reduce the temperature and solidify the charcoal.

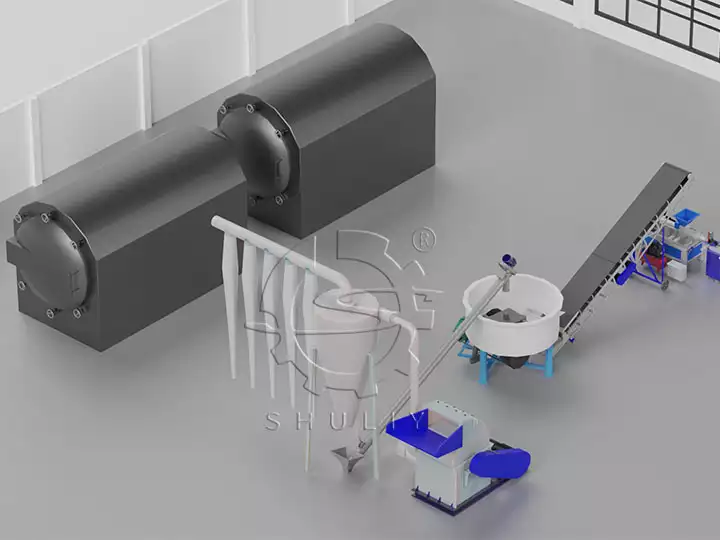

If you want coconut shell charcoal briquette, you need to continue:

Step 6: Mixing and grinding

If regular coconut shell charcoal is required, the cooled and cured coconut shell charcoal can be mixed and ground to obtain the desired particle size and shape with wheel mixer and grinder.

Step 7: Coconut shell charcoal briquette making

As needed, the treated coconut shell charcoal can be further processed into various coconut shell charcoal products, such as charcoal fuel, charcoal balls or charcoal briquettes. During this process, the charcoal making machines(like charcoal briquette extruder machine, BBQ charcoal machine) are required.

Step 8: Charcoal packaging

Finally, the fabricated coconut shell charcoal products are packaged and labeled, ready to be shipped to the market for sale. Packaging is usually chosen based on product type and market demand to protect the product and enhance the sales image.

What kind of carbonization furnace is the best for coconut charcoal?

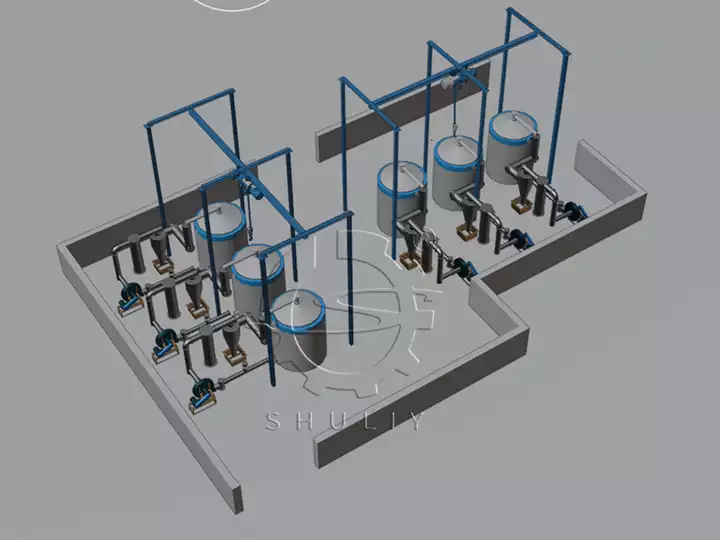

For making coconut shell charcoal, the most suitable type of charcoal furnace is continuous charcoal furnace or vertical charcoal furnace.

These coconut shell charcoal making machines provide a stable temperature and atmosphere to ensure that the coconut shells are fully decomposed and converted into high-quality coconut shell charcoal during the charring process.

| Types of coconut shell charcoal making machines | Advantages of this coconut charcoal machine |

| Continuous charcoal machine | 1. High stability: Continuous carbonization furnace can continuously provide stable temperature and atmosphere to ensure that coconut shells are well heated and decomposed during the whole carbonization process. 2. High degree of automation: The coconut shell carbonization machine is usually equipped with advanced automatic control system, which can realize fully automated operation and reduce manpower investment and production cost. 3. High production efficiency: This coconut charcoal making machine can produce continuously without stopping to wait for the end of carbonization, which has high production efficiency and is suitable for mass production of coconut shell charcoal. |

| Vertical carbonization furnace | 1. Flexibility: Vertical charcoal furnace has simple structure and flexible operation, which is suitable for small-scale or individual production scenarios, and the production volume can be adjusted at any time according to the needs. 2. Low investment cost: Shuliy coconut charcoal machine maker is usually cheaper than continuous carbonization furnace, which is an economical choice for customers with limited capital. 3. Wide range of applications: This charcoal carbonizer machine is suitable for carbonization of many kinds of raw materials and products, not only for coconut shell, but also for carbonization of wood, straw and other kinds of biomass raw materials. |

Benefits of coconut charcoal

Coconut shell charcoal has many advantages, including but not limited to the following:

- Firstly, it is environmentally friendly as it is made from coconut shells, a natural renewable resource.

- Secondly, coconut shell charcoal produces high and long-lasting heat when burned, providing stable heat.

- Thirdly, the combustion of coconut shell charcoal is virtually free of smoke and odor, which is harmless to the environment and health.

Shuliy coconut shell charcoal making machine price

The coconut shell charcoal machine price depends on the model, production capacity, configuration and other factors. And our charcoal machine price is competitive in the market, because we provide a wide range of models and configurations of coconut shell charcoal machines.

Compared with other suppliers, our charcoal machine price floats within a certain range and is cost-effective. You can choose the suitable model according to your needs and budget. Also, you can tell us your needs, and we will help you choose the most suitable coconut shell activated carbon machine.

How to start a coconut shell charcoal making business?

To open coconut shell charcoal manafacturing plant, the following tips for your reference:

- You need to conduct market research to understand the market demand and potential customer base of coconut shell charcoal.

- Choose suitable coconut shell charcoal making machine and suppliers to ensure the reliable quality of the equipment.

- Make a detailed production plan and marketing strategy, while focusing on product quality and after-sales service, and gradually start the coconut shell charcoal production business.

If you need any help, contact us at any time for more information!

Coconut charcoal machine feedback from worldwide customers

Brail customer uses Shuliy continuous carbonization furnace

Get a quote now!

If you have a demand for coconut shell charcoal production or are interested in our charcoal machines, please contact us immediately, we will provide you with detailed product information and quotation, as well as professional consultation and service.