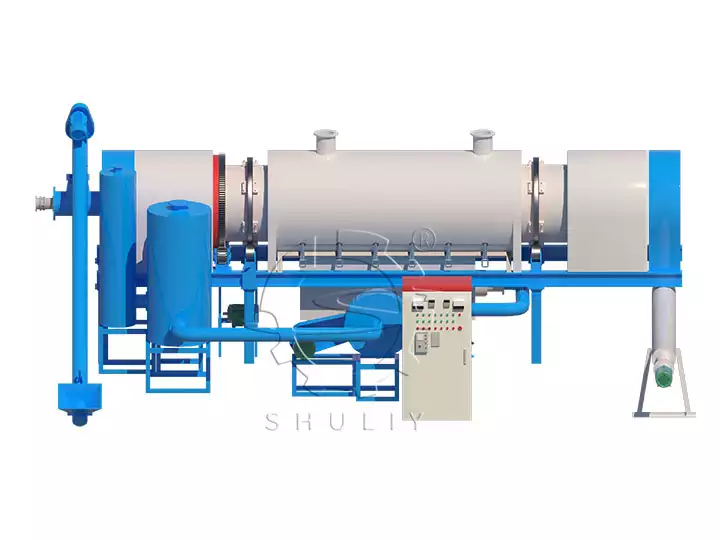

This continuous carbonization furnace is great equipment for carbonizing wood chips, sawdust, coconut shells, rice husks, palm kernel shells, bamboo chips, etc into charcoal as fuel. Its capacity is 600-1200kg per hour, and one batch of charcoal takes 15-20min.

Using this kind of charcoal carbonization furnace, the raw materials size is ≤5cm and the moisture is ≤20%. The charring ratio of this carbonization furnace for wood charcoal is 1:3. Our carbonization stove features customization, wide applications and suitable capacities.

Also, our charcoal carbonization machine has been exported to many countries, such as Zimbabwe, the UK, Kenya, Indonesia, Uganda, Guinea, etc. If you’re interested in our charcoal machine, get in touch with us now!

What is a carbonization furnace?

The carbonization furnace(charcoal kiln, charcoal furnace) is a kind of equipment used to convert organic raw materials (such as wood, bamboo, etc.) into charcoal. During the carbonization process, the organic raw materials are heated at high temperatures without burning, decomposing solid charcoal and gas products.

This equipment is usually used to produce charcoal products such as wood charcoal, bamboo charcoal, etc. It is characterized by high efficiency and energy saving, and is widely used in agriculture, industry and energy fields.

Technical parameters of continuous carbonization furnace

Model: SL-800

Capacity: 600-800 kg/h

Diameter: 800mm

Charring temperature: 500-800℃

Main power: 18.5kw

Fan power: 5.5kw

Model: SL-1000

Capacity: 800-1000 kg/h

Diameter: 1000mm

Charring temperature: 500-800℃

Main power: 18.5kw

Fan power: 5.5kw

Model: SL-1200

Capacity: 1000-1200 kg/h

Diameter: 1200mm

Charring temperature: 500-800℃

Main power: 20kw

Fan power: 5.5kw

From the above data, this coal carbonization furnace has a capacity of 600-1200 kg/h, and the carbonization temperature is 500-800℃. Because the inlet diameter has a certain range, the raw material should be below that. If you want more information, please contact me for more classifications.

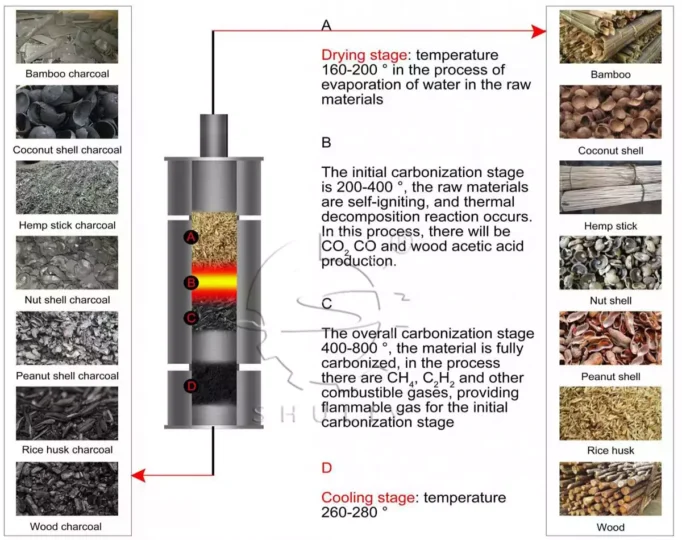

Raw materials suitable for continuous carbonization stove

Wood shavings, wood chips, bamboo, peanut shells, corn stalks, sesame stalks, rice hulls, coconut shells, tea cinders, cottonseed hulls, soybean hulls, hemp hulls, sunflower hulls, cotton seed hulls, pineapple hulls, rubber tree wood shavings, tea tree branches, grapevine branches, apple branches, peach tree branches, sawdust. Bagasse, twigs, bamboo shavings, sorghum stalks, sunflower seed shells, wine lees, corn cobs, sorghum stalks, apricot shells, coffee residue, cotton stalks, soybean stalks, yam grass, withered leaves, Chinese medicine dregs, hemp stalks, palm shells, e-waste, cans, waste electrical wires, sludge, domestic waste and other materials with biomass properties are carbonized. Diameters below 15mm granular are available.

Unique carbonization furnace design

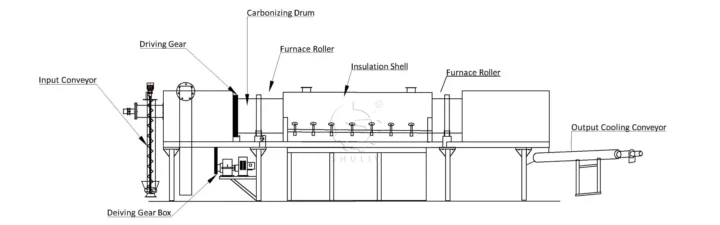

- The unique design of the Continuous Carbonization Furnace lies in its highly efficient continuous heating system, which is able to continuously provide a stable high-temperature environment to ensure full carbonization of the raw materials.

- In addition, the interior of the furnace adopts a patented design of the trough structure, which enables the raw materials to be heated evenly and maintains good airflow circulation, improving carbonization efficiency.

- Meanwhile, the carbonized boiler is also equipped with an intelligent control system, which can automatically monitor the temperature and operation status to ensure safe and stable operation.

- The overall design is compact, covers a small area, easy to install and maintain, and is suitable for the carbonization production of various raw materials.

How does the coal furnace work?

A continuous carbonization furnace is a device used to produce coal, which works by subjecting coal or other organic materials to high temperatures so that they undergo a pyrolytic reaction to produce coal. The process of continuous carbonization can be described:

- Inside the furnace, the burning material (usually wood or gas) provides heat, which raises the temperature inside the furnace.

- Subsequently, raw materials (e.g., wood sawdust, wood chips, plant straw, etc.) are placed into the furnace and undergo a carbonization process in a high-temperature environment, ultimately converting them into coal.

- At the same time, the gases inside the furnace are released and processed for use as fuel or other purposes.

The entire process requires control of parameters such as temperature, ventilation and heating rate to ensure that a compliant coal product is produced.

Working principle of continuous carbonization furnace

Here describe the whole carbonization process, and the carbonizing process lasts 15-20 min. The details are as below:

Ignition

First, the biomass material is ignited in the gasifier, because the continuous charcoal carbonization machine needs to be warmed up, which takes about 1 hour. The whole process only needs to be ignited once.

Preheating stage

The preheating is completed when the preheating temperature reaches 280°-330° and the raw material is put in.

When the raw material is coconut shell, the furnace temperature is 330° to put in the raw material; when the raw material is palm shell and lighter raw material such as rice husk and wood chips, the furnace temperature reaches 280° to put in the raw material.

Ignite the combustion chamber

After 10-20 minutes of carbonization, when hot gas is observed to be generated in the burning pool, ignite the gas to make the combustion chamber burn.

Turn off the fire head and do not use it again because the combustible gas that is generated by the carbonation process of flue gas by spraying, cooling and purification process can burn secondary.

Carbonization process

Continuous carbonization can then take place. Each round of carbonization takes 20 minutes.

Discharge and cooling

The discharge has a cooling process, which is carried out through a condensation tube, with a double-layer structure. The interior contains the carbonized feedstock and the exterior is cooled by water.

Advantages of carbonization furnace for charcoal

- High efficiency and energy saving: adopting advanced carbonization technology and energy-saving design, it can realize high-efficiency carbonization reactions and maximize energy and cost savings.

- Environmental protection and low emission: the charring furnace adopts a closed design, which can effectively control the emission of waste gas, reduce environmental pollution and meet the requirements of environmental protection.

- Automatic operation: this continuous carbonization furnace is equipped with an intelligent control system, which is easy to operate and can realize automatic production, reducing labor costs and labor intensity.

- Applicable to a variety of raw materials: it applies to a variety of biomass raw materials, such as wood, straw, wood chips, etc. It is flexible and meets the needs of different users.

- Stable and reliable: using high-quality materials and precision processing technology, the equipment runs stably and reliably with long life and good performance.

How about the carbonization furnace price?

The price of a charcoal furnace depends on several factors, including the model of equipment, production capacity, configuration options, and manufacturer. Usually, larger models and higher configurations of charcoalizing furnaces are more expensive, but will bring higher productivity and performance.

Before purchasing a continuous charcoal furnace, it is best to communicate with the manufacturer in detail for specific quotes and configuration information.

Shuliy Machinery: carbonisation furnace manufacturer and supplier

Shuliy Machinery is a professional manufacturer and supplier of charcoal furnaces with many years of production experience and rich technical strength.

We offer various specifications and models of continuous carbonization furnaces, which can meet the production needs of different users. Meanwhile, we also provide perfect after-sales service to ensure that our customers get timely support and help in the process of purchase and use.

Global cases: continuous carbonization furnaces sold worldwide

Our continuous carbonization furnace has been sold to many countries and regions around the world, and has been well received by customers. Our equipment plays an important role in the carbonization processing of various biomass resources and creates abundant economic benefits and social value for customers.

The continuous charring furnace was exported to the UK, providing an efficient solution for local biochar charcoal production and helping its eco-friendly energy production.

Zimbabwe introduced a continuous carbonization furnace to realize the resource utilization of indigenous waste agricultural and forestry materials and promote local sustainable development.

The continuous charcoal furnace entered the Indonesian market, providing innovative technology and efficient equipment for local coconut shell charcoal production, and boosting the development of the renewable energy industry.

Related equipment for charcoal making

Besides continuous charcoal furnace, we also have horizontal carbonization stove and vertical charcoal furnace.

Besides the biomass carbinzation furnace, Shuliy Machinery also provides all kinds of equipment related to charcoal making, including wood crusher, charcoal briquette making machine, charcoal ball press machine and so on. These equipment can be used together to form a complete production line to realize efficient production and processing of charcoal.