This rice husk charcoal making machine is used to carbonize rice hulls, and other organic materials into charcoal through high temperatures.

With various charcoal making equipment for sale, we can produce rice husk charcoal/charcoal briquettes with our rice husk charcoal machine. Thus, if you’re interested in charcoal production, contact us at any time for more details!

How is rice husk charcoal made with carbonization furnace?

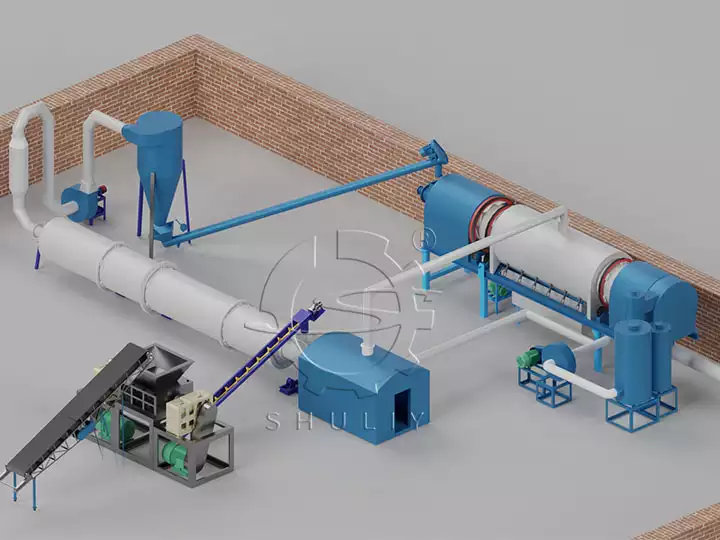

To make rice hull charcoal, there are two ways to make coal briquettes with Shuliy rice husk charcoal making machine. Now let me introduce in detail:

The 1st way: carbonization first, then rice husk charcoal briquetting

1. Carbonization

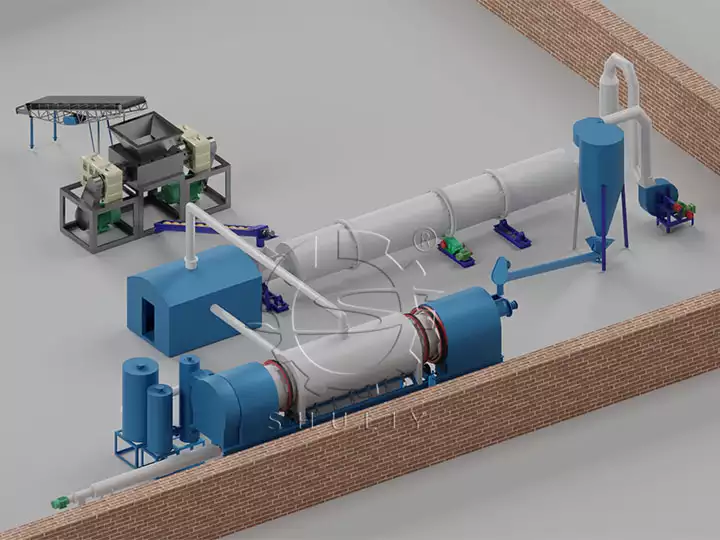

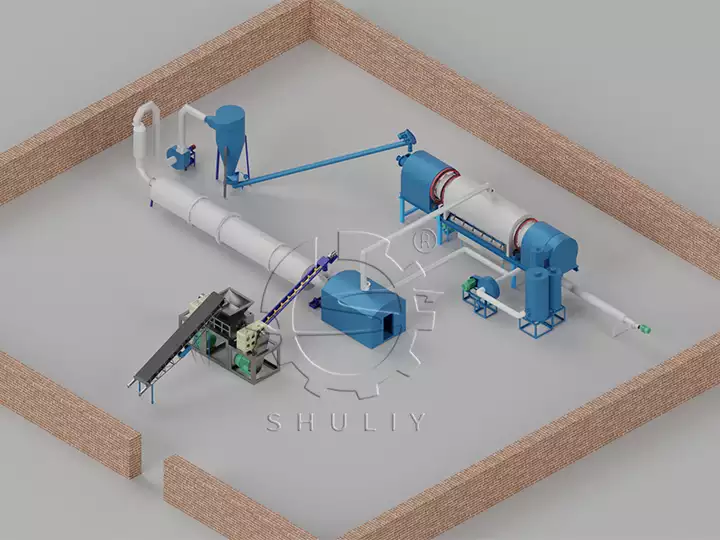

Because of the small size of rice hulls, it can be directly put into the carbonization furnace for carbonization. Moreover, according to the characteristics of rice husk, continuous carbonization furnace is usually used for carbonization, where rice husk is gradually transformed into rice husk charcoal through high temperature and oxygen-deficient environment.

2. Mixing and grinding

Subsequently, if you want to make rice husk charcoal briquettes to be used as fuel, the srice husk charcoal powder is required. Thus, you should use the rice husk charcoal grinding machine to process.

3. Rice husk charcoal briquetting

Finally, use the charcoal briquette machine to make rice husk coal briquettes with various shapes. This method is simple and efficient, and can produce directly from rice husk to charcoal rods, saving time and labor costs.

The 2nd way: briquetting first, then carbonizing

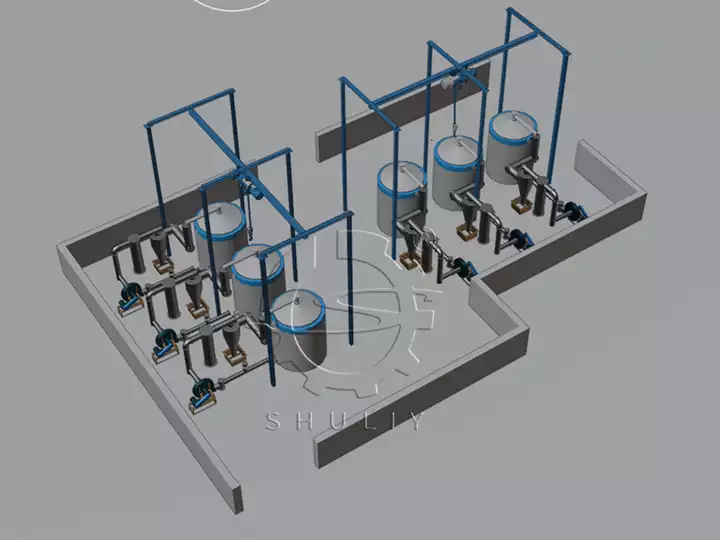

1. Rice husk briquttes making

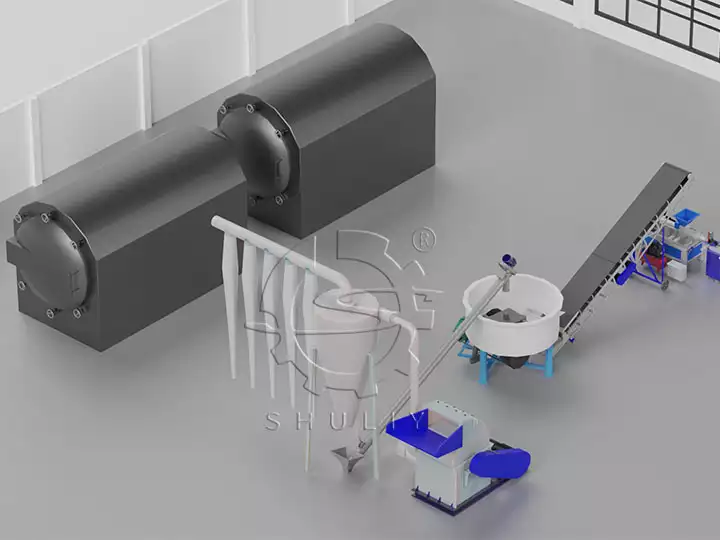

Firstly, the rice husk is compressed into lumps and pressed into rice husk charcoal briquettes using rod making machine.

2. Carbonizing

Then, the made rice husk charcoal briquettes are fed into a hoisting charcoal furnace or a horizontal charcoal furnace for carbonization.

In the rice husk charcoal carbonization machine, the rice husk charcoal briquettes are gradually transformed into high-quality rice husk charcoal under high temperature and oxygen-deficient environment. This method can better control the carbonization process and improve the quality and yield of the charcoal compared to the first method.

Why turn rice husk into charcoal?

Because using rice husk to make coal with rice husk charcoal making machine has multiple benefits:

- Firstly, rice husk is usually regarded as a waste product, which may cause pollution to the environment if not handled properly. By converting rice hulls into charcoal with rice husk carbonizer, it can realize the reuse of resources and reduce the emission of waste, which is conducive to environmental protection and sustainable development.

- Secondly, as a high-quality biomass fuel with high calorific value, low ash content and low sulfur content, rice husk charcoal is suitable for a variety of thermal applications, such as barbecue and field heating, which helps to improve the efficiency of energy use.

Therefore, the conversion of rice husk into charcoal not only contributes to environmental protection, but also creates economic value and enhances energy utilization efficiency.

What are the rice husk charcoal uses?

Rice husk charcoal has a wide range of uses, mainly for barbecue, field barbecue, home heating and heat energy in industrial production.

Due to its long burning time, high heat and low smoke, it has an important application value in various occasions.

How about rice husk charcoal making machine price?

The price of charcoal rice husk machine varies relative to different models and configurations, which is mainly affected by the type of machine, production capacity, brand, market supply and demand and other factors.

Generally speaking, the price of large, high-capacity rice husk charcoal making machine is higher, while the price of small, low capacity machine is relatively lower.

But the specifics of the price should be specifically analyzed, if you want to know the price of the rice husk charcoal maker, contact us to tell us your needs (final product, use, budget, etc.), and we will provide you with the optimal solution according to your specific needs.

Why choose Shuliy as rice husk charcoal making machine supplier?

- High-quality equipment and technology: We have advanced rice husk charcoal making equipment and technology, which can produce high-quality rice husk charcoal with high efficiency and ensure stable and reliable product quality.

- Rich experience: Shuliy has rich experience and technology accumulation in the field of rice husk charcoal production, and can provide professional services and solutions for you.

- Competitive advantage: Our rice husk charcoal machinery is reasonably priced and competitive, and we also offer flexible trading methods and personalized services to meet your different needs.

- Professional team: We have a professional team that can provide you with a full range of technical support and after-sales service to ensure your satisfaction and trust.

Get in touch with us for more rice husk charcoal machine information!

For more information about charcoal making, please feel free to contact us, we will provide you with detailed answers and professional services.