The wood charcoal machine is the equipment used to convert wood, hardwood, wood branches, etc. into charcoal. Generally, we use vertical carbonization furnace, continuous charcoal kiln or horizontal charcoal furnace for wood charcoal making, based on specific situations of wood materials.

Through the process of heating, carbonization and cooling of wood materials, our wood charcoal making machine can efficiently transform wood raw material into high-quality charcoal products with good stability and burning performance.

Types of wood charcoal making machines for sale

For wood material to be carbonized, we often use the wood carbonization machine. There are commonly 3 types of charcoal kilns used to turn wood into charcoal. According to the wood materials, you can choose the suitable charcoal furnace.

These three types of wood charcoal machines have their own characteristics, you can choose the right type according to your production needs and site conditions. See details below:

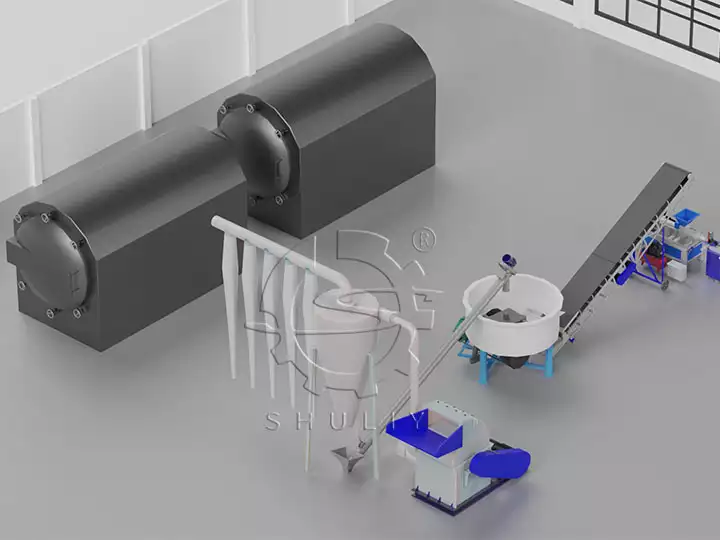

Horizontal charcoal furnace for making hardwood charcoal

Horizontal charring furnace is suitable for small-scale production and home use. Its advantages are:

- High efficiency and stability: This small charcoal making machine adopts horizontal design with large charring capacity, which can produce charcoal continuously with high production efficiency.

- Easy to operate: Just put in the wood and ignite the fire, the charring process will be carried out automatically without too much human intervention.

- Energy-saving and environmental protection: The carbonizer machine adopts indirect heating method, which reduces energy consumption, lowers emission and meets the requirements of environmental protection.

Vertical carbonization furnace for making wood charcoal

Hoist charcoal furnace is a kind of equipment suitable for small and medium-sized production with high automation and production efficiency. Its advantage is:

- Strong flexibility: Hoist wood charcoal machine has simple structure and good mobility, which is suitable for mobile production or limited space.

- High combustion efficiency: During the process of carbonization, the fuel is fully burned, the carbonization efficiency is high, and the output of charcoal is of good quality.

- Wide range of applications: This charcoal making machine from wood can be applied to different types of wood, including logs, wood chips, etc., with strong applicability.

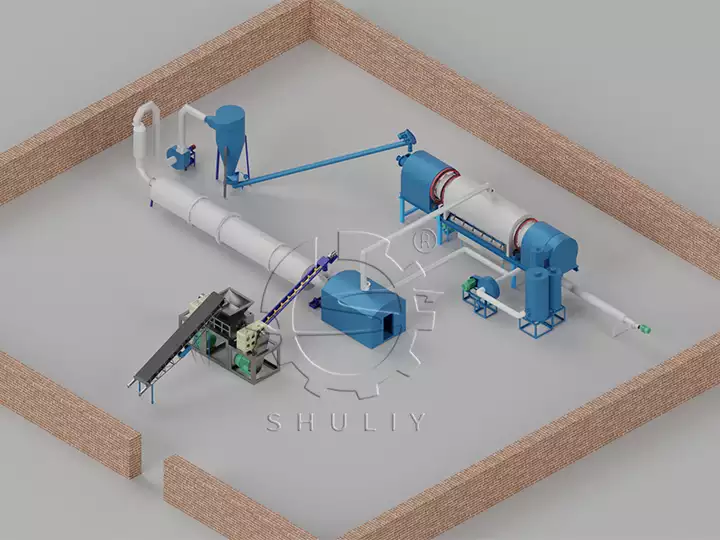

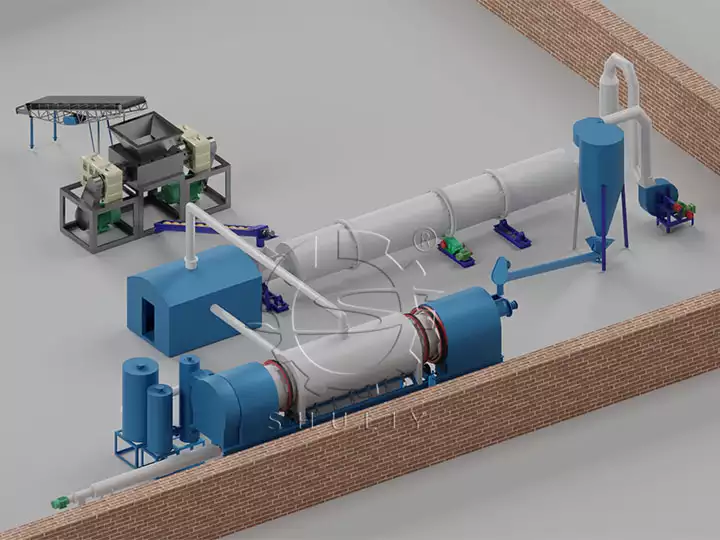

Continuous charcoal kiln for making charcoal

Continuous charring furnace is a kind of equipment suitable for mass production, which can realize the fully automatic production process. The advantage is:

- Continuous and stable production: carrying out the carbonization process in a continuous and stable manner greatly improves production efficiency and capacity.

- Stable finished product: because of continuous carbonization, the charcoal is highly stable.

- High energy utilization: this charcoal maker can be continuously recycled to reduce resource waste, which is suitable for industrialized production and commercial operation.

Raw material suitable for wood charcoal machine

Raw materials suitable for the lump charcoal making machine mainly include the following wood-based materials:

- Logs: including the whole wood of various trees, such as pine, cypress, birch, etc.

- Wood shavings: small pieces of wood shavings formed after wood has been cut, milled or processed, such as those produced in the production process of furniture factories and wood factories.

- Wood chips: thin pieces of wood formed after wood has been planed or cut, such as wood chips produced in the production process of wood chip boards.

- Wood cubes: wood material neatly cut into blocks, such as wood fuel or wood pellets.

- Wood sawdust briquettes: rods formed by pressing wood materials into shape, such as wood pellets pressed into sticks or wood fuel sticks.

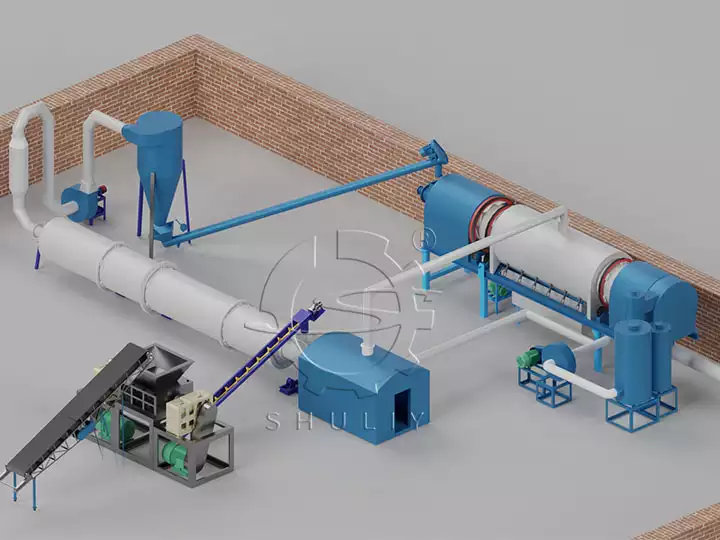

What’s the wood charcoal making process?

Raw material preparation

In the wood charcoal making process, the first thing you need to do is to prepare the applicable wood raw materials.

The raw materials can be various wood-based materials, including logs, wood chips, wood chips, wood blocks, etc.

Crushing & drying(if required)

The prepared wood raw materials will be fed into the pulverizer for crushing and fine crushing, so that the wood will be turned into particles or powder suitable for carbonization.

After crushing, the wood particles need to be dried to remove the moisture. Usually rotary dryers or other drying equipment are used for drying.

Charring

Choose a suitable wood charcoal manufacturing machine for carbonization.

Through the high temperature and low oxygen environment in the wood charcoal machine, the wood or particles gradually lose their moisture and volatile substances, and are eventually converted into charcoal.

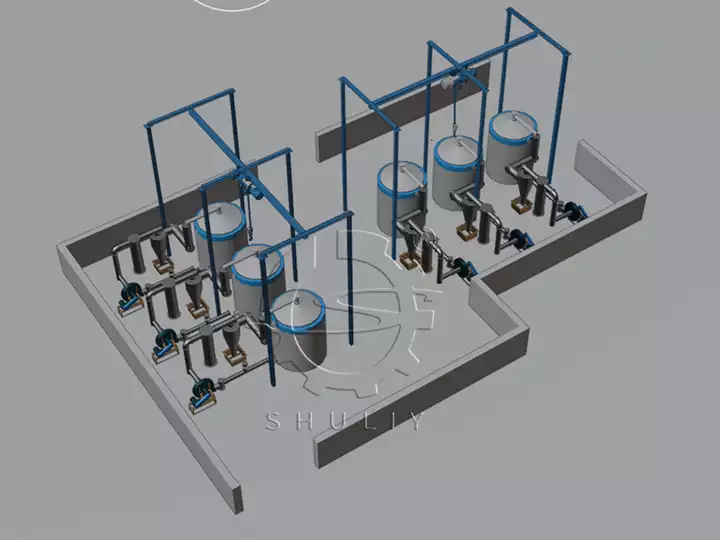

Cooling and curing

After carbonization, the charcoal needs to be cooled and cured to achieve the proper hardness and density.

The cooling process is usually carried out by natural cooling or by using specialized cooling equipment.

Molding(optional) and packaging

The cooled and cured charcoal can be molded and packaged to make different shapes of charcoal products, such as charcoal balls, charcoal briquettes, etc., according to the needs, and packaged and encapsulated for storage and transportation.

Something about wood charcoal machine price

- Equipment model and specification: the price of biochar making machine will be different for different models and specifications, usually, the equipment with higher production capacity and more functions will be relatively higher in price.

- Production capacity: The higher the production capacity of the wood chips charcoal making machine, the higher the price may be, because equipment with high production capacity usually requires more materials and processes to manufacture.

- Equipment quality: Shuliy, as a famous brand, focuses on product quality and performance, so the price of hardwood charcoal making machine from Shuliy may be slightly higher compared with some low price competitors.

- After-sales service: Shuliy provides perfect after-sales service system, including installation and commissioning, training, etc. These service costs will also affect the price of wood charcoal making machine.

All in all, the price of Shuliy wood coal making machine may be slightly higher, but also can get better quality assurance and perfect after-sales service support.

Where to buy cost-effective wood charcoal machine?

If you want to buy cost-effective charcoal machine, you can consider choosing Shuliy as your charcoal resort kiln supplier.

As a professional charcoal buring machine manufacturer with many years of industry experience and rich production experience, Shuliy can provide high-quality carbonization machines and professional after-sales service. In addition, our charcoal making equipment is relatively reasonable in price and cost-effective, so it is a good choice.

How to start wood charcoal business?

Before starting a wood charcoal business with wood charcoal machine, you should:

- Local market research: Understand the demand for charcoal in the local and target markets, including consumption trends, competitors and price levels.

- Finding raw materials: Identify available wood sources, such as branches, wood chips, sawdust, etc., and ensure the quality and adequate supply of raw materials.

- Purchase equipment: Choose wood charcoal machine that suits your size and budget, such as charcoal furnace and sawdust briquette making machine.

- Wood charcoal making: According to the operation manual of the sawdust charcoal making machine, carry out the production process such as pretreatment of raw materials, carbonization, molding and packaging.

- Marketing: Promote your hardwood charcoal products through various ways, such as social media, offline sales, etc. to attract more customers.

- Customer service: Maintain good communication with customers, solve their problems and feedbacks in time to improve customer satisfaction and reputation.

- Business expansion: According to the market demand and development trend, constantly adjust and optimize the production and sales strategy to expand the business scale and market share.