我们的锯末机制炭机通过高温连续炭化将木屑制成炭。我们的锯末炭化炉的产能为800-1000公斤/小时。由于使用连续制炭机,原材料,即木屑,对其尺寸≤5厘米和水分≤20有要求。

作为专业的木炭机制造商,我们提供两种解决方案来制造木屑木炭以获取利润。你有兴趣吗?如果是,请立即联系我们了解更多详情!

用锯末制造木炭的解决方案

根据木炭制造方式的不同,我们可以有两种不同的方式通过锯末木炭机加工木屑,如下图所示:

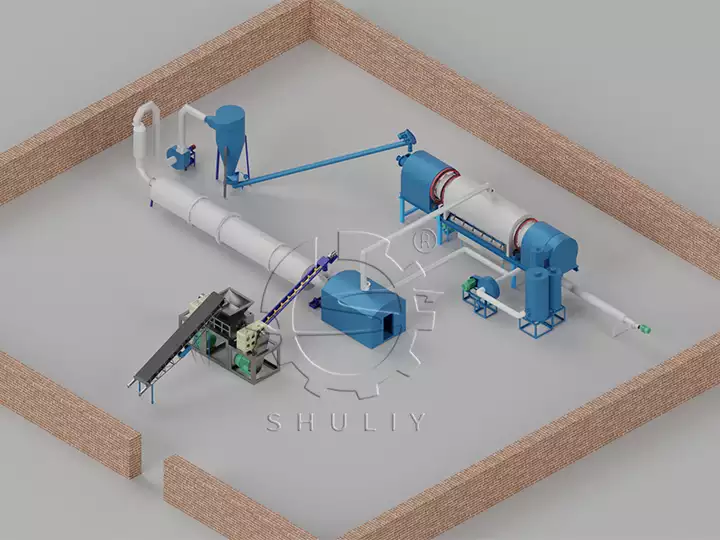

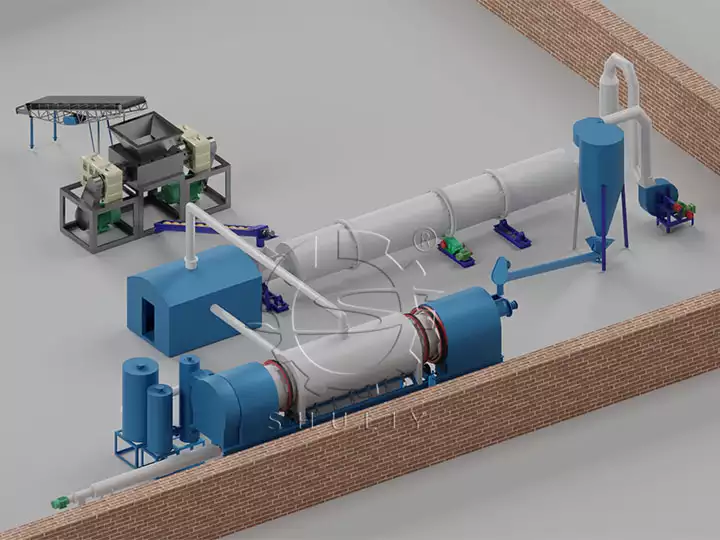

方案一:碳化压块

因为我们的原料是锯末,所以这种制作锯末木炭的思维方式就是先炭化再压块。这个解决方案是:

- 选择合适的木屑制炭机将木屑炭化,然后冷却并收集。

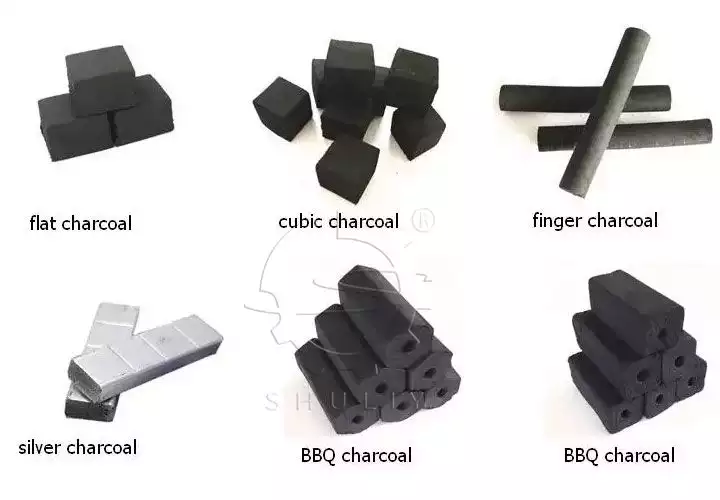

- 接下来,使用合适的木炭压块机将锯末木炭制成各种形状,木炭的最终形状取决于您的需求。

最终产品如下图所示:

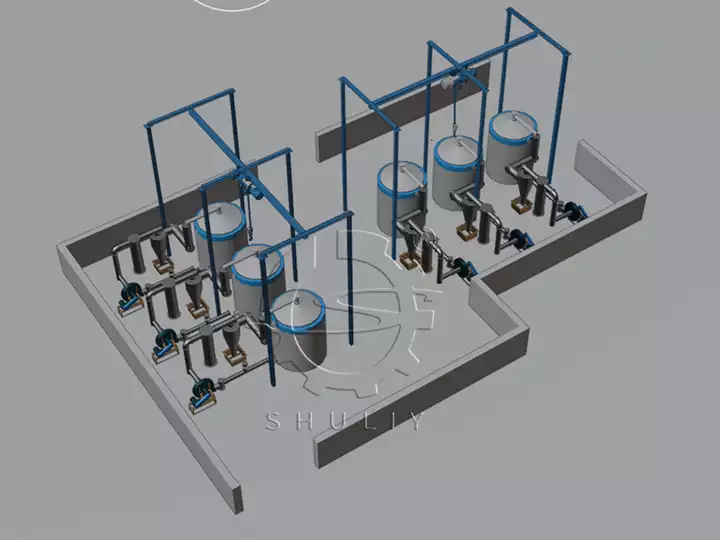

解决方案2:压块和炭化

这种方式是直接生产木屑型煤。将生物质成型燃料木屑原料制成生物质成型燃料,然后进行炭化,操作步骤如下:

- 将生物质原料放入木屑成型机中,经高温高压压缩成棒,然后干燥收集。

- 然后,生物质棒在锯末木炭机中炭化,最终产品是锯末型煤,可以作为燃料出售。

每个步骤的最终产品如下图所示:

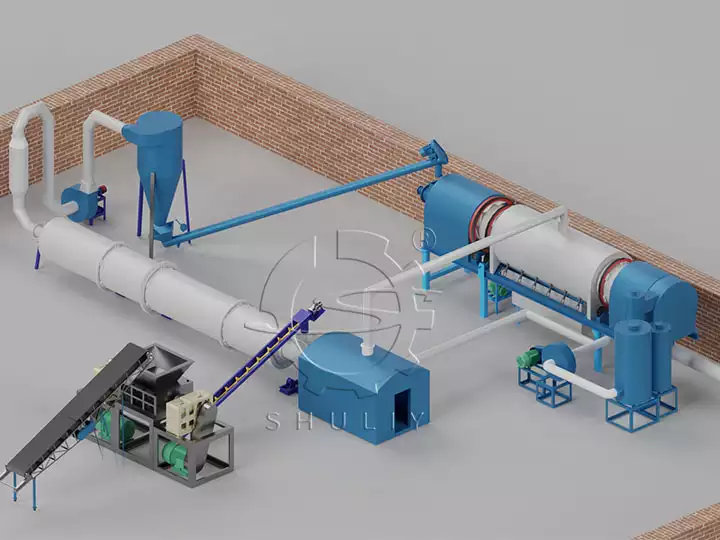

制煤过程中使用的木屑制炭机

通过以上两种木屑制炭的方式,木屑制木炭的机器不同,解决方案也不同。

解决方案1使用的木屑制炭机

小型制炭机用于生物质制炭,包括连续炭化炉和木炭压块机。

连续式炭化炉用于炭化锯末,木炭压块机负责将锯末木炭成型为预期形状的木炭。

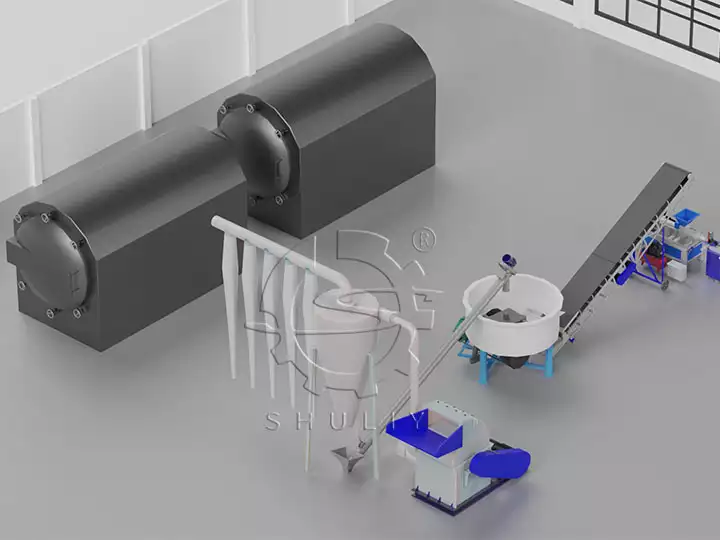

解决方案2使用的Sawdsut生物质木炭机

这种方式使用生物质成型机和锯末成型木炭机(即立式木炭炉或卧式木炭炉)。

我们的锯末压块机将生物质压缩成压块,然后使用立式炭化机将其炭化成锯末压块炭。

木屑制炭机的优点

- 高效节能:采用先进的炭化技术,木屑木炭机可实现高效节能的生产过程,最大限度地提高生产效率,降低能耗。

- 多功能性:适用于多种原料,如木片、木薯渣等,具有很强的适用性和灵活性,可以根据不同的原料生产出优质的木炭产品,满足市场需求。

- 环保节能:锯末木炭生产过程减少了废气和废水的排放,并采用资源循环利用技术,符合环保要求,有利于可持续发展。

- 木炭品质稳定:我公司的木炭炉采用先进的生产工艺,可生产出密度高、强度稳定的煤炭产品,深受客户青睐。

用锯末生物质制造木炭的好处

利用锯末生物质制造木炭有很多好处:

- 资源丰富:锯末等生物质废弃物来源广泛,利用这些废弃物制造木炭可以充分利用资源,降低成本。

- 高效利用:以木屑等生物质废弃物为原料,通过生物质炭化技术,实现高效利用,将废弃物转化为有价值的木炭产品。

- 优良的产品品质:用锯末制炭机生产的木炭密度高、热值高、燃烧时间长、质量稳定,适合多种应用场景。

- 经济效益显着:木炭是生活和工业中广泛使用的产品,利用木屑生物质制造木炭可以创造稳定的经济效益。

- 减少废物:利用锯末等废弃物制造木炭,有效减少废弃物堆积,对改善环境起到积极作用。

通过生物质制炭机利用木屑生物质制造木炭,不仅可以有效解决资源浪费和环境污染问题,而且可以创造经济价值,促进可持续发展。

从木屑中提取有利可图的木炭产品

使用锯末制炭机生产木炭的最终目的肯定是为了盈利,所以这里介绍了一些在全球市场上可以用锯末生产的流行木炭形状。

感兴趣的?联系我们了解更多详情!

如果您的答案是肯定的,请立即联系我们!告诉我们您的需求,例如最终的炭形状、预算等,我们将提供最佳的木炭制造解决方案。